What is Biomanufacturing and Precision Fermentation, and why is it important?

Biomanufacturing allows for more refined products to be created as a part of bio-based and agricultural businesses. Precision fermentation, a popular processing technique, does more than just make corn into ethanol for fuel. Specialized bioprocessing can create more advanced types of food protein, new types of textiles and fibers, more modern polymers, and commercial grades of oils/lipids, pigments, and even cosmetics. This breadth in output allows for more market stability in bio-based businesses.

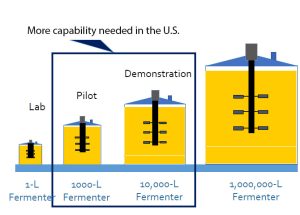

Lack of Fermentation Infrastructure is Bottlenecking the Industry

Jay Keasling, a chemical engineer at Lawrence Berkeley National Laboratory and the founder of several bio-based chemical companies, says many of the ventures he’s been affiliated with have done their scale-up work in Europe because they couldn’t find adequate facilities in the US.

The U.S. has an opportunity to bring large-scale biomanufacturing back to facilities located in the U.S., offering faster turnaround, lower costs, higher ROI, and easier access to both resources and results.

IBRL is a state-of-the-art bioprocessing facility, among the largest in the nation, and can easily scale to meet different biomanufacturing needs.

Precision Fermentation is at Our Core

We help companies scale fermentation processes and identify downstream processing technologies through pilot testing. Fermenters range from 19.5 to 1500L.

We are building a pipeline of de-risked companies for scaling:

- Demonstration testing (10,000 to 75,000L)

- Commercialization (100,000L+)

Limited pilot and demonstration scale testing are hindering industry expansion in Illinois.

Growing the Illinois Bioprocessing Hub

Pilot Plant Expansion:

Double size – fermentation focus. Increase client and workforce throughput.

Demo Scale Partnership(s):

Working with state, local, and industry leaders to develop demo-scale facility and infrastructure support in Illinois

Workforce Development:

Expand student intern program, create additional short courses and expand educational programs.

IBRL’s Expansion Plans

Build a 35,000 ft2 facility proximal to IBRL to expand testing and training capacity to meet industry needs. Actively working with Biomanufacturing Initiatives (i.e. BioMADE, Corn Refiner’s Association) to identify funding sources.

Benefits of Expansion:

- Expand testing capacity from 2,932L to 12,312L

- Increase footprint from 40,000ft2 to 75,000 ft2 including:

▪ More & Larger Fermenters

▪ Varied DSP equipment

▪ Large spray dryer

▪ Space for additional employees

▪ Larger educational spaces - Expand workforce development through full-time employee growth from 20 to 50, student training from 35 to 100 per year, and increase industry training from 80 per year to 180 per year.

- Extend pilot services from 20 to 60 companies per year

Market Opportunity in Precision Fermentation

- $1.6B → $11.8B Anticipated Industry Growth in Value, from 2022 to 2048

- One million jobs by 2030

According to KBV Research; July 2022. Jobs figure per Rogers, J. N., Stokes, B., Dunn, J., Cai, H., Wu, M., Haq, Z., & Baumes, H. (2017). An assessment of the potential products and economic and environmental impacts resulting from a billion ton bioeconomy. Biofuels, Bioproducts and Biorefining, 11(1), 110–128. https://doi.org/10.1002/bbb.1728

Capacity Growth: Why Illinois is Ideal

Significant Technological Competitive Edge

- No. 2 in corn production

- Abundant feedstock

- Unmatched intermodal transportation

- Competitive energy cost, abundant water

- Major industrial bioprocessing companies with commercial facilities