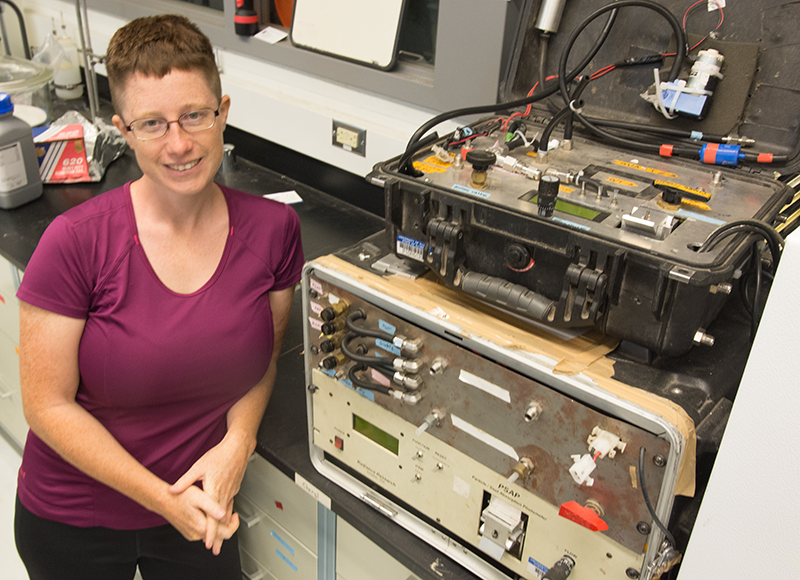

Cheryl Weyant with two “boxed” emission measuring field kits. The bottom unit (tan) was used between 2012 and 2014 to measure kilns and cook stoves in Nepal, and the top unit (black) was built a few years later and used to measure cook stoves in Tibet and India. Certainly a well-traveled team!

Illinois graduate student Cheryl Weyant never pictured her career leading her to the top of a rickety, two-story scaffold surrounding a giant kiln exhaust stack in rural India. And yet, in the spring of 2011, that’s exactly where she found herself — carefully inserting a pollution emissions sensor she built herself to measure the harmful gases and microscopic particulate matter going up with the smoke.

Structures like the one Cheryl climbed on that day are common in India and Nepal, where kiln-fired bricks are the main construction material. Passed down from generation to generation, these businesses have changed their operations very little over the centuries. “Green” unfired bricks are piled high in a 10-foot trench, and coal or wood is moved around the large ring to bake them into long-lasting hardness. As some bricks finish firing, they are unloaded and new bricks piled in their place. The fires burn continuously during the brick-making season — releasing emissions that cause respiratory infection and lower the health of not only the kiln workers, but their families and other locals.

To earn her Ph.D. in Environmental Engineering from the University of Illinois at Urbana-Champaign, Cheryl is capturing some elusive data: how much air pollution — and what kind — coal-fueled Indian and Nepalese brick kilns contribute to the atmosphere. To do so, she’s had to develop some of her own methods and tailor sensing technology to her needs.

Her journey into the field of emissions study began “by complete accident,” she said. “I meant to become a hydrologist.”

After completing a B.S. in Agricultural Engineering at the U of I in 2008, she went to work for the Illinois State Water Survey testing water samples from field observations.

“Then, I heard about an opportunity (in Professor Tami Bond’s lab) to build some equipment for emission sampling and take it into the world to test. I said to myself, ‘That sounds fun and engaging. I bet I can do that.’ And so I signed up,’” Cheryl said.

The task seemed simple enough: take prototypes developed by two previous graduate students; customize them for brick kiln sampling; and streamline them for extra portability. Little did she know that her work would be part of the solution to a long-running problem in the field of emission study.

IN-HOME EMISSIONS ARE TRICKY TO MEASURE

For years, Bond, a Professor of Civil and Environmental Engineering at the University of Illinois, and members of her lab were interested in measuring the emissions from household fires around the world. More than 3 billion people cook their daily meals over open fires, and Bond wanted to know what impact the resulting combustion gasses and soot exposure were having on the atmosphere and people’s health.

“We knew that these sources had a contribution but we didn’t know how much – we didn’t have a way to find out,” she said. “There was no feasible way to go out to rural homes in India with a truckload of equipment that had to run on electricity.”

Therefore, science’s best guess for many years came from emission data created with fires lit under huge laboratory fume hoods. The funneled exhaust would be analyzed to determine the level of different pollutants produced by a specific amount of fuel. Were these lab-perfect results actually representative of what was happening in the world, though?

“I wanted to go to the field,” Bond said. “I wasn’t expecting a big difference between the lab-generated emission factors and what we’d observe in the field, but I thought we ought to go check.”

It turns out, early tests showed that in-field emissions were a lot higher than emissions in the lab. A lot more measuring would need to be done, and Bond’s lab began to travel the world with a home-brewed system of hoses, bungee cords, and particle sensors. All packed onto a rolling cart and powered by a car battery, this system worked well for residential measurement, but to tackle measuring industrial-scale brick kilns, the team was going to need something new.

Enter Cheryl Weyant.

HAVE SENSORS, WILL TRAVEL

When she arrived at the lab space on her first day, she was greeted with a large collection of probes, hoses, sensors, and wiring — and no idea how to use any of it. Right away she traveled with a research team to Nepal to learn the ropes of field emissions measurement.

“I had to build the whole system at every place we went to,” she said. “It was a pain! I thought our results would be better if you always had the same arrangement.”

Working from a single-box prototype built by a previous member of the lab, Cheryl pulled all the pieces needed for kiln emission testing into a single unit. About the size of a mini fridge, and weighing a bit more, it held a variety of equipment neatly inside, with user controls and air input hookups on the front face.

The “boxed” design was first developed to enable Bond group members to measure emissions from cooking in rural homes. The challenges it solved were also typical of brick kilns. First, both residential cook stoves and kilns don’t burn at a constant rate. Emission levels fluctuate as both cooks and kiln workers stoke their fires “every so often.” Cheryl’s system had to be able to measure reliably for several hours at a time to make sure both peaks and low points were measured.

Second, gases emitted from the kilns would mix with outside air at almost the same moment they were created — meaning that the particles she actually needed to measure would be diluted with ambient air. To compensate, the box included instruments sensitive enough to detect the emitted pollutants at very small concentrations.

With those challenges solved, Cheryl confronted additional hurdles once she took her sensor box on the job in India. The most significant was a problem with moisture in her air samples. Combustion of any fuel is a wet reaction — it creates water vapor. Cheryl’s original plans had accounted for that, but she didn’t anticipate the additional water being evaporated out of the clay bricks also entering the exhaust fumes.

“It’s a problem for your air intake tubes to be full of water. So, the answer is to draw in some outdoor air, clean it, dry it, and add it to the exhaust sample,” Cheryl said. “I had to rearrange some components in the box on the fly to make room for a bigger mixing chamber for the two air samples to make sure there was enough dilution for the amount of water vapor we were seeing.”

“I’d never done anything like this before,” she said, “although I did have a background in engineering. I feel like I’m kind of good at it from certain perspectives. I’m good at troubleshooting: finding what’s wrong and solving those kinds of puzzles.”

IMPROVEMENTS IN ACTION

After some preliminary tests in the lab to check that sensors were registering properly and the system was air-tight, Cheryl’s kiln-specific model work got its first field test on the day in 2011 she clambered up the side of a traditional brick firing kiln in the Varanasi district of India.

“Having to make calculations about how to set up a new test site, it’s kind of fun. Even with the ready-to-go sensor box, I still have to determine the best setup: About how concentrated are the pollutants and how much should they be diluted? How long can I run without overloading my filters?” she said. “You have to be a little visionary, but under a weird time constraint. Working in a space that is challenging, but where you are meeting the challenge, is incredibly fulfilling.”

The primary goal of the Indian kiln project was to measure the air pollution levels from several kilns to determine which model was healthiest for the community.

“What we found was the kilns we expected to be very polluting could be run pretty cleanly, depending on some key characteristics and the operation of the kiln,” Cheryl said. “The opposite was also true. The so-called ‘improved’ designs to be more fuel- (and emissions-) efficient could be undermined by poor operation.”

The team’s full results were published in an Environmental Science and Technology article in 2014, providing data for atmospheric simulations of air quality all over South Asia. Before, inputs to these models — and predictions of how air quality would improve if interventions were made — were based on guesses.

By unlocking the best measuring methods for kilns, Cheryl’s work has paved the way for additional study and improvement. Partner organizations like the International Centre for Integrated Mountain Development (ICIMOD) have adopted the technology and expanded measuring efforts to redesign kilns for healthier communities.

A RESEARCH LEGACY

The field-optimized “boxed” emission sensing equipment pioneered by Cheryl and her peers in the Bond Lab has laid the groundwork for new research the world over. The design solved a lot of problems plaguing remote emission research. Although the first models were still pretty bulky (the latest version can fit in a large backpack!) it was much more compact than anything else that existed. It was battery powered, and therefore could measure for many hours without access to electricity.

New students have expanded and changed the designs of the kits to meet their particular needs, replacing bulky equipment with newer, streamlined technologies and adjusting the configuration of components. The Sensor Box is now on its sixth iteration — although it’s hard to say for sure, said Cheryl, because boxes get pulled apart and put back together so often! Creativity is constant.

Since the very first field box was developed by Chris Roden nearly 10 years ago, Bond and her students have visited five countries, and taken more than 200 hours of emissions data from cooking fires, brick kilns, and power plants.

Ryan Thompson, an alumnus of the Bond Lab, started his own company called Mountain Air to sell emission sensors commercially to other academic and government research branches.

“What we’ve done is put method in where there was none before,” Bond said.

“Emission testing used to be limited to sources that had an exhaust stack and burned continuously, like a coal power plant. But there are a lot of sources in the world, particularly abroad, that don’t work that way. The operation is highly variable; so if you take a single sample you don’t get a representative one,” Bond said.

“Cheryl’s work… has been about formalizing methods for chasing those different sources.”

Said Cheryl: “Emissions are impossible to predict, they’re just too complicated. Every time we have measured we have found something we didn’t expect. (Scientists are) making the best predictions we can, but nothing compares to measurement. And the more we measure and understand, the better the rest of the guesses will get.”