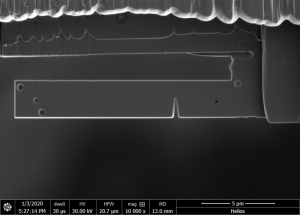

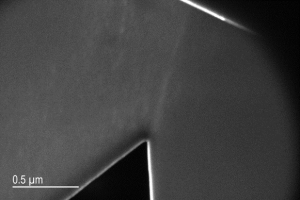

In collaboration with Prof. Shen Dillon, the overarching goal of the work is to develop fundamental chemistry-structure-property relationships for UO2 grains and grain boundaries that serve as a basis for optimizing chemistry and engineering microstructure for damage tolerant fuels. Small scale testing is be employed to isolate the mechanical properties of individual microstructural features such as the fracture toughness along specific crystallographic directions in the bulk and along grain boundaries of known crystallographic character. Experiments performed as a function of dopant chemistry and processing conditions (e.g. temperature and/or oxygen partial pressure) will be used to develop fundamental structure-property relationships that will form the basis of experimentally derived cohesive zone models that can be used to predict bulk mechanics at the finite element scale. For select samples, temperature dependent measurements will also be performed in the regime relevant to reactor conditions, T>1200 oC, and potentially under concurrent ion irradiation/implantation. Throughout the work the existing and newly developed methodologies will be tailored in a way that will allow them to be implemented in the LAMDA Facility at ORNL. This project is supported by the ORNL Advanced Fuels Campaign.

FIB UO2 cantilever specimen prepared for micro-mechanical testing. Image provided by Prof. Shen Dillon, UIUC MSE.

SEM image of notch at a grain boundary in a UO2 cantilever specimen. Image provided by Prof. Shen Dillon, UIUC MSE.

Post failure SEM image of a notched UO2 cantilever specimen. Nano-indenter shown in lower portion of the image. Image provided by Prof. Shen Dillon, UIUC MSE.