The 3.4-L recirculating loop autoclave is dedicated to corrosion studies of nuclear materials. The autoclave currently supports research related to IASCC of 308L/309L weldments and pristine 316 stainless steel under NEUP sponsorship. This system has a 50 kN load frame with a 10,000 lb. load cell and dual strain gauges with a sensitivity of order 10-4. The Inconel 635 pressure vessel is rated to 30 MPa at 600 ºC. The maximum flow rate is 6L/hour. The load frame control system is capable to tensile stress-strain measurements and cyclical loading. In addition, the system has a direct current potential drop controller to perform direct current potential drop measurements of crack growth rates. Water analytics include inlet and outlet pH, dissolved oxygen, and water conductivity sensors. The recirculating loop has two parallel deionizer cartridges. Inlet and outlet water conductivities are typically less than 200 nS/cm during immersion tests. The water column has a gas inlet to introduce dissolved oxygen and hydrogen and a head pressure control valve to set DO and hydrogen concentration. Dissolved boron and alkalinizing agents can easily be added to the water loop and the DI cartridges can be taken off-line. Four specimen holders are available: two single tensile holders for regular and irradiation specimen sizes, a CT holder, and a four-sample tensile holder. The recirculating loop autoclave is currently supporting research on the behavior of advanced steels in LWR envirnoments.

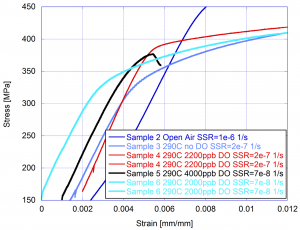

Stress-strain data of 304L stainless steel in different water chemistry environments and different SSRs.

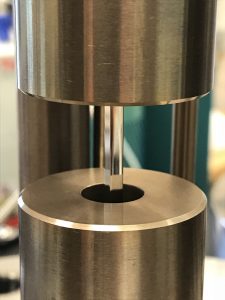

Tensile specimen (left) and strain gauge apparatus (right).