The objective of this project is provide experimental data on the performance of Alloy 308/309 and 82/182 weldments during exposure to environmental factors typical of normal LWR operation in support of the LWRS Program. In particular, the work scope is designed to determine inter-granular stress corrosion cracking (IGSCC) susceptibility with respect to radiation damage and LWR primary coolant chemistry. The goal is to correlate crack initiation and IGSCC to 1) grain boundary orientation, 2) local grain boundary chemistry and oxidation, 3) and localized deformation, and 4) dpa displacement cascade damage. The experimental protocols are designed to separate the effect of irradiation and associated radiation damage from environmental factors such as LWR water chemistry and applied load and to determine the synergistic effect of irradiation, water chemistry, and tensile stress. In addition, modeling activities are proposed that capture salient features of the materials response of these alloys to LWR environments. The combined experimental and computational methodology is anticipated to improve the predictive capability of Grizzly using a novel extended finite element method (XFEM). The proposed project will be supportive to the LWRS Program in two ways. First, it will expand the knowledge base to include the behavior of weldments found in LWRs. Second, it will serve as input into a modeling component to this project, which in turn will lead to enhanced predictive capability of Grizzly.

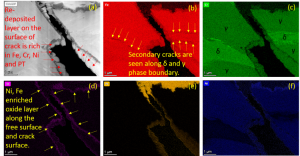

Figure showing primary and secondary cracking of a mixed phase 309L weldment butter. (a) STEM-HAADF micrograph of crack in 309 butter layer, (b) STEM-EDS Fe map, (c) STEM-EDS Cr map, (d) STEM-EDS O map, (e) STEM-EDS Pt map, (f) STEM-EDS Ni map.