Hi everyone! This semester really opened my eyes to a lot of technologies, ideas and concepts. Before coming into this class, I had a strictly logical mind. Creativity and innovation were never at the forefront of my brain. However, this was necessary to do in this class. Walking into class the first day, I was intrigued by the 3D printers and prints around the room. The printers seemed so foreign and complicated to me. However, after two weeks of class I was comfortable printing a design on the printer.

Getting a “maker mindset” is harder than you may think. Although, being surrounded around my classmates with similar mindsets made it easier to become a “maker.” This is one of the first classes I have been in where the students actually were invested in their projects and actively trying to make their projects better. This wasn’t a forced project; it was something everyone was fully invested in. Being surrounded around this made it easy and fun to get into the class.

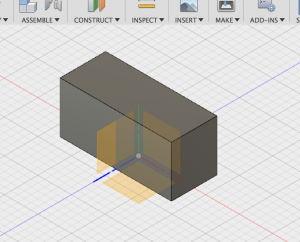

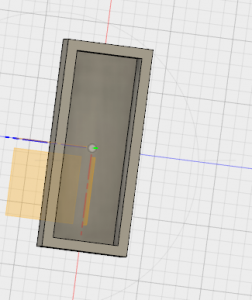

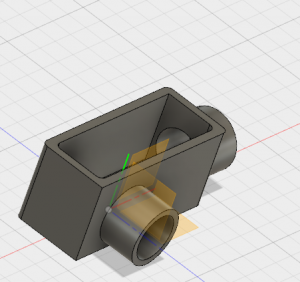

The designing aspect of the course was the most difficult part of the course for me. Because most of the classes I have taken have not been focused on building the physical product, I was not aware of all the struggles and roadblocks that can and will happen in the designing process. Learning Fusion 360 was an interesting experience. I was not able to come to class that week, so I learned it all on my own. I watched multiple YouTube videos and learned the basics of Fusion 360.

The first thing I made was a keychain shaped like an ‘M’. This first print was simple, but it was super cool to see my design come to life. After that, I watched my classmates print more complex things every week. Seeing the final projects BLEW my mind and I was so happy to have been there through the whole process. It is amazing to me how creative a group of students can get.

Exploring thingiverse and pinshape was a fun activity as well. You don’t realize how many things makers have made. Having these websites allow makers to build off of other maker’s ideas and designs. Before this class, I didn’t realize 3D printing was as prevalent as it is and seeing all of these designs made me excited about the future of 3D printing.

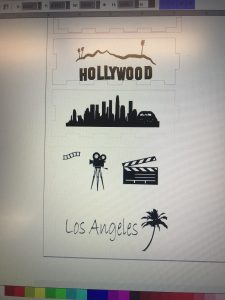

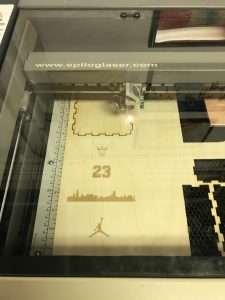

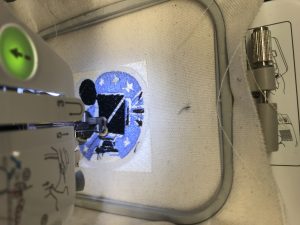

The three weeks at the FabLab were my favorite weeks of the whole course. We created a box with an embroidered top with LED lights. Every week we learned a new skill, allowing us to explore all that the FabLab had to offer. Although I had trouble with the digital embroidery, it was my favorite part of the FabLab. Creating something that is unique to you is invaluable and unique.

The guest speakers we had in this course were also very interesting. Not only did I enjoy getting pizza whenever we had a guest speaker, but I enjoyed the unique perspectives of makers across the country. My favorite speaker was Arielle. She was very inspirational with her entrepreneurship capabilities. She took a small problem that a small group of people had, and created something amazing and effective for it. Arielle was one of my group’s inspirations for our final project. In addition, Jeff Ginger was very enthusiastic about the Fablab and the maker community, which translated to us, making us curious about it as well.

Overall, this class was very beneficial. It allowed me to stretch my imagination and take a class that wasn’t like my regular curriculum. It allowed me to work with other students and build off of their creative thoughts. I believe this class is beneficial for all future business men and woman because we will eventually be managing engineers and designs. Knowing the design process is helpful in this case. Thank you to all my fellow classmates for taking this journey with me and I wish you all the best!