This week, our guest presenter was Jeff Ginger, the director of the CUC Fablab. I really enjoyed Jeff Ginger’s presentation. What I found most interesting about the Fablab was the collaborative nature of the workspace. I was exciting to hear about his research focus in community informatics and user experience design. Jeff’s take on education in the public-school system was also quite interesting. I agreed with his perspective that there isn’t enough courses to foster creativity, entrepreneurial thinking, and the maker mindset amongst students.

I think the Fablabs mission to enable all individuals to imagine, design, and create using open source software methodologies is powerful work encouraging more people to adopt a maker mindset. I have visited the Fablab because of my involvement in Illinois Enactus, a project based social entrepreneurship organization. Stay glassy, a project in our portfolio for Enactus owns a wet-saw and utilizes Fablab space to up-cycle leftover glass into viable products for retail. It was also amazing to hear that the Fablab is comprised of a network of numerous spaces across the nation.

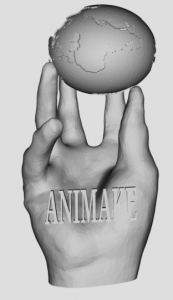

The readings and videos this past week refined my understanding of how 3D printers work and reminded me how revolutionizing 3D printing tech is. With Tinkercard and Cura I learned how to design and convert digital prototypes into svg files to be 3D printed. In reading about Tinkercard, I was able to import and edit a png image. The ability to edit the size, color, and shape of an image allowed my team and I the ability to create our customized logo. The logo design is below and it took approximately six hours to be printed.

The how 3D Printers Work video explained how 3D printers use an additive manufacturing process to create objects from nothing. The main types of 3D printing technologies include SLA: Stereo Lithography, SLS: Selective Laser Sintering, and FDM: Fused Deposition Modeling. These methods all utilize lasers to create objects from scratch. The motherboard guides the print head in motions based upon the digital design.

3Ders.org is a website that lays out the basics of 3D printing. It explores what 3D printing is and provides an overview of its history. This digital resource is very easy to comprehend and incorporates videos to explain concepts.

Link: https://www.3ders.org/3d-printing-basics.html

Another resource 3D printing resource I came across is startasys. Stratasys is a 3D printing knowledge center that has instructional videos, case studies, and education materials to learn more about 3D printing. Specifically, the educational resources provide an in-depth curriculum on STL files, adobe Photoshop, and project ideas relating to 3D printing.

Link: http://www.stratasys.com/resources

Hi Jason,

I think your logo is really cool and l like how you imported and existing image to create your logo instead of starting from scratch. I’m interested in seeing how it turned out in person because the design looks very detailed and I am wondering if the team name is 3D or not. I also liked the resources you talked about because they are good educational tools for people to learn more about 3D printing.