My Expectations and Experience:

To be completely honest walking into Digital Making Seminar, I had relatively high expectations for Badm 395. However, looking back in retrospect I can know confidently proclaim that all my expectations had been superseded. Originally, I wanted to take Digital Making Seminar because I had very little background knowledge in 3D printing and wanted to gain a more comprehensive understanding of innovative and groundbreaking technology available today. I had envisioned Digital Making Seminar to be class that only encompassed 3D printing and different business solutions that could be formulated from 3D printing, but that was only the tip of the iceberg. This class transcended the provisional scope of my expectations for this class: we covered CAD Software, Circuiting, Arduino and Breadboards, Laser Cutting, Design Thinking, Rapid Prototyping and so much more that I will touch upon in just a little bit. Coming into class, I thought Digital Making Seminar would be an excellent opportunity to allow me to gain comprehensive knowledge in the digital world but relatively unrelated to my post graduation plans. However, as I leave class I know realize that everything I learned in Digital Making Seminar is SO APPLICABLE. I will be going full-time in July doing technology consulting and the digital practice in all technology consulting practices are growing exponentially. With all this being said, I can’t wait to have the potential opportunity to explore digital practices within IBM so that I can apply skills that I’ve gained in this class to the workplace enviorment. Looking back on this class now, I am so glad I took the opportunity to continue to expand my horizons and challenge myself as a second semester senior, make so great friends, and of course take another great class with Professor Vishal who inspired me to become an Information Systems major (and you can’t forget about the pizza either! haha).

My Learning:

CAD Software

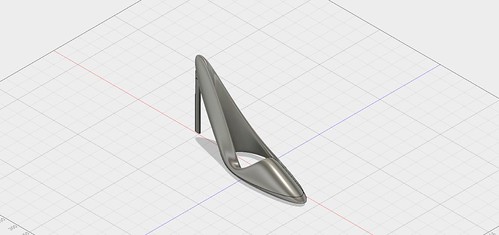

In CAD, I learned how to utilize TinkerCad and Fusion 360 software. While difficult at first, I was able to ultimately successfully craft both the tutorial structure as well as my own personalized heel prototype in Fusion 360 after a couple of iterations and failures. While perseverance truly led me to create the prototypes, without the help of Jeff Smith and all his excellent teaching of AutoDesk Fusion 360 there would have been no way I could have accomplished the following two prototypes:

Circuits & Coding with Arduinos:

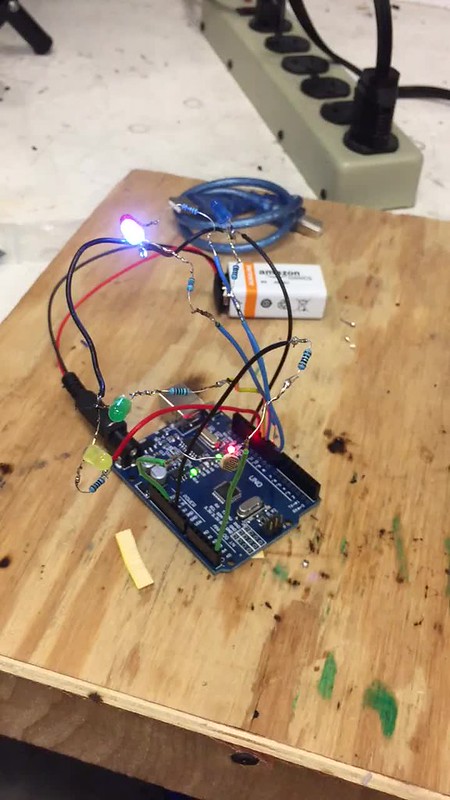

The Fab Lab was an absolutely unbelievable experience. The amount that I was able to learn in three weeks was amazing. From never soldering wires before, I was able to not only successfully solder wires but also successfully wire both an arduino board and breadboard to act as a light sensor, with LED lights indicating on a spectrum whether little to a lot light was present within a room. Additionally, I was able to get my hands dirty and do some coding in Arduino to program the arduino to have that specific functionality. While I had a little bit of coding experience in VBA and R previously, Fab Lab really gave me the opportunity to have a 360 degree view of the digital world and all the innovative steps the digital community is striving to make a difference in today’s world.

3D-Expression:

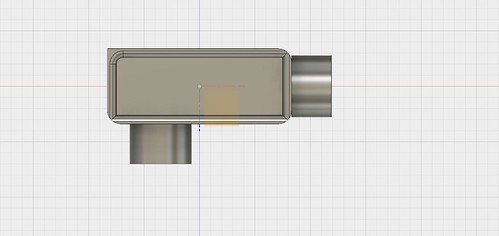

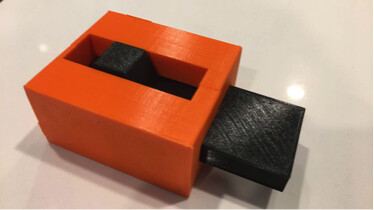

In Laser cutting and wood engraving, I learned that while the digital revolution is innovative and groundbreaking it’s always imperative to have fun with technology. And, what better way to have fun with wood engraving and laser cutting that to express yourself: Here is my arduino board circuit box with images that best describe myself:

Big Data and Its Implication on 3D printing:

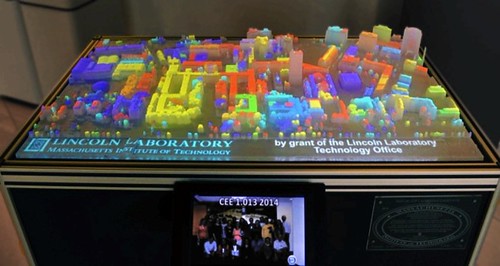

For my own personalized project, I examined how 3D printing and Big Data complemented each other in today’s business world. It was amazing to see what MIT students had accomplished with data visualization and 3D printing. By printing a 3D structure of the campus of MIT and overlaying it with unstructured Twitter Data, so many powerful insights could be drawn on students at MIT:

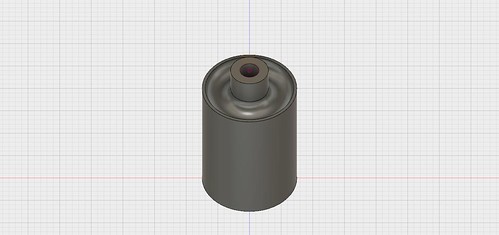

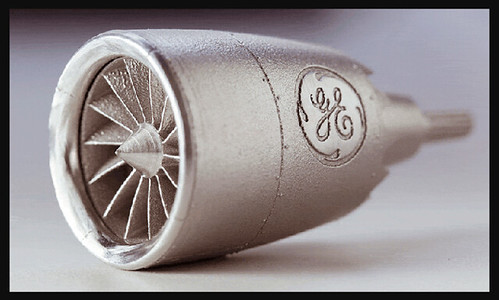

Additionally, General Electric was also utilizing Big data to help rapidly prototype some of its turbine engine parts take a look:

Innovation By Simplicity:

Through Team Supra’s DoorJar, I learned that innovation doesn’t always have to fall in the category of groundbreaking or new-to-the-world product development. But much rather sometimes, the greatest innovations truly stem from simplicity. For instance, innovation by simplicity yields easy constructability, low costs, and room for continuous improvement without drastically increasing the price. And in turn, commercializing these innovations and bringing them to market they also have a high likelihood of generating profits for a company. And, that is exactly why Team Supra chose to create DoorJar.

Design Thinking & Rapid Prototyping:

Lastly, Design Thinking & Rapid Prototyping are two crucial concepts that I learned in class that will be carried over in my life post graduation. Realizing how design thinking and agile software develop framework (which I was fortunate to work in this summer) go hand in hand was truly a unique experience as well to see how applicable the concepts we were learning in Digital Making Seminar truly applied in the real business world. Rapid Prototyping opens opportunities in manufacturing to medical to renewable energy to software development and so many other industries, and I honestly cannot wait to have an opportunity to utilize rapid prototyping again.

Personal Professional Development & Growth:

Lastly, the greatest thing I learned in this class cannot be quantified by a subject title or concept. But much rather, Digital Making Seminar taught to continually challenge myself, expanding my horizons, and keeping my mind open. I remember all the times I walked into Fab Lab and thought to myself “no way can I solder wires together”, “no way do I know how to circuit arduino board and I definitely don’t know how to code it”, “I have no experience in Fusion 360 of CAD software how can I possibly be good at this?” But it’s because that I had the courage to try and challenge myself that I was able to solder wires, circuit and code and arduino board, and even help build DoorJar’s prototype in TinkerCad. By keeping my mind open in the future and my hunger for learning, there are so many opportunities in life that will be opened for me in my future.