March 27th, 2017: What a great day to get right back into 3D printing! After a spring break hiatus of approximately 14 days, it felt great to start small remaining duration of second semester senior year in the maker lab! To be honest, I definitely missed the maker lab as we had not had class there since mid February. Olivia and I had the opportunity to turn on our creative juices this week as we began to design and catalyze initial prototypes for our final semester project.

We decided to revisit our consumer trash-compacting business solution product. Bouncing myriad ideas off each other, Olivia and I spent the first 100 minutes of class drawing different prototypes and documenting ideas on how we wanted our product to be created and what capabilities the end product had to encompass. Team Supra wanted to develop a product that had the following 4 key features: 1. A trash disposing device that is easily reachable by price and desirable by the everyday consumer. 2. A device that compacts trash significantly more than other competitor household trash devices do. 3. This trash compaction allows for significant higher amounts of volume to be stored in one trash bag. And lastly, 4. This “storage volume” saving results in economic savings and “environmental” wellness for the consumer. Through all the brainstorming and prototyping Olivia and I were able to come to following idea. Here is a picture of our prototype:

And this is the motivation for our prototype:

We ultimately envisioned a device that would have natural openings at the top of the trash can for trash disposal. At the very top of the trashcan, a 25 pound weight would sit and be ready to compress trash. This weight would then connect to an “upside down” umbrella like material. Thus when compression took place the “upside down umbrella” would open easily conforming to any trashcan type and shape allowing for universal and dynamic use on different types of trashcans. The weight would descend upon the trash through the utilization of the lever crank on the side of the trashcan. The lever provides the consumer the capability to easily compress and pull back the weight to its original position. As a lever provides torque on the lever and pulley of the weight a consumer would be able to easily compress and release its trash from the lever. Lastly, with the selection of trashcan above placement of the weight would allow for aesthetics and ergonomics. The weight would not get in the way of the consumer when disposing trash. And the weight could easily compress trash and returning to its resting position.

With all this being said, we ecstatically presented our idea to Professor Vishal and received some excellent feedback. While our product certainly solved the business problem at hand, our prototype was already begin to demonstrate the infeasibility to reach the proper price point and generate enough demand we desired. In order to reach the everyday consumer, our trash device had to be a product price of a maximum of maybe $20 (accounting for switching costs and over valuation of old products of current consumers). With that being said, the complexity of our product was already demonstrating high costs that may potentially already superseded $20. Thus, it was became evident that our product would most likely not be able to retail at $20. Additionally, the trash market is heavily saturated already. While our idea certainly provides an innovative way to compress trash, maximize trash bag effectiveness, and allow consumers to cut costs and be more environmentally friendly, what is going to stop a consumer from simply using a dirty mop to compress trash on their own? With that being said, Professor Vishal recommended us explore new ideas as we were still in the prototyping stage.

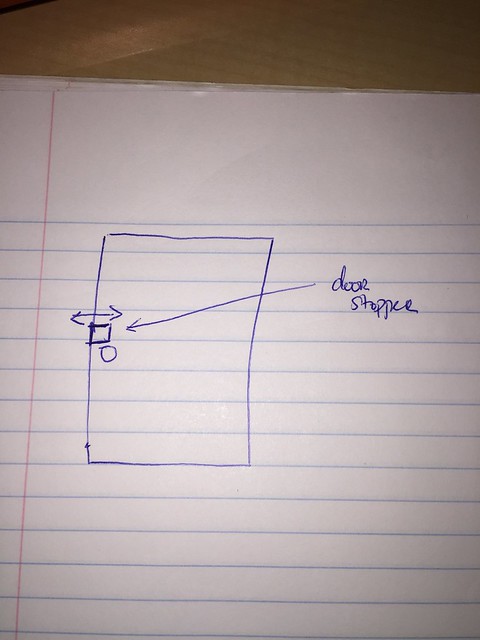

And, I think this is one of the greatest aspects of design thinking and rapid prototyping. It gives flexibility to fail early, make the mistakes now, learn from mistakes, and start over. And that’s exactly what we did. With only a few minutes left in class, Olivia and I searched through our brainstorming thoughts and identified a new idea to design and prototype. We decided to recreate the door stop with enhanced functionality to if you may “master” the door stop. Analyzing current door stoppers, we realized the biggest issue they face is that they’re not durable and over time they do not hold the door. With this, we saw an opportunity to create a door stopper that would ultimately sit in the middle of a door as opposed to the ground. View image below:

It would be made of out very strong material for increased durability, slide back and forth for easy door stopping capabilities, and be made of a clear and transparent material allowing aesthetic appeal. While this concept may seem fairly simple, Team Supra plans to take this idea and run with it giving it the best functionalities possible at the lowest cost possible, and making it dynamic so it can become an universal product. Placing a very low price of approximately $1-2 allows for consumer switching costs to be overcome. After Team Supra perfects this product to the best of their capabilities we will look into security capabilities of the door stopper. For instance, the creation of a door lock checking system for any consumer enabled through bluetooth technology and sensors. The number of times I leave my apartment or garage at home and can’t seem to remember if I closed the door/garage is astronomical. Stay tuned for more of Team Supra’s innovations next week!

Hi Ben, I think this is a perfect case of why it is so important to receive outside feedback. As David Kelley said in the design presentation we watched, iterative design and receiving feedback quickly and as often as possible is so important to success. I think its good that you realized the problems you faced quickly and decided it was better to try a different product idea. Success does not come to those who give up after their first failure! Your new product idea has a lot of potential. Have you considered looking into whether or not it can be labeled as ADA compliant since it won’t require someone to bend to the floor to use it? I’m excited to see how you innovate what so many consider a simple, everyday object.

I really like both of your group’s ideas. It’s a shame that the trash compactor will probably be too difficult to create in a feasible manner, but the idea and drawings you created were certainly cool. And yes, the flexibility of the initial design phase is probably the greatest aspect of design thinking. You get to explore all the different nuances of the problem you’re trying to solve, and if you encounter something difficult/unexpected, you can start to work around it or create something new. Looking forward to an update!

Hi Ben,

I definitely agree with you that it’s been awhile since we’ve all been at the FabLab and it’s nice to be back to start working on our projects. When your group had spoke about your idea I was really excited to see what type of product you would create for the trash can. However, it is great to see that your group had considered the price points, the demand of the market and came to a conclusion that it may not be the best product to create. It’s always good to know that the creators are taking the consumer’s needs in their hand. Can’t wait to see your future innovations!