With only approximately 8 weeks time, Team Supra sought to rapidly research, design, prototype, and bring to life a prototype that would effectively fulfill a business need, bridge a gap in consumer needs, and ultimately turn profitability for a business in the long run.

Ideating Process:

In the Ideating Process, Team Supra wanted to identify a business need in a consumer segment that was comprehensively understood. As Veronika, Olivia, and Ben are all college students, Team Supra decided to evaluate college-aged students who were living on a budget in a house or apartment. After observing consumers’ behaviors for a several days, Team Supra pursue a household trash compactor:

Team Supra agreed that trash is a common college struggle especially with full utilization of trash bags. Thus, Team Supra set out to create a trash compacting device that allows for greater trash bag “storage volume” to be achieved, leading consumers to have cost savings and environmental wellness at a reasonable price. However after receiving feedback from Professor Vishal, we realized that 8 weeks was not enough time to construct a product with numerous variables such as cost, size, and strength.

Refocusing & Designing with Innovation By Simplicity

Team Supra decided to tackle a new problem that commonly occurred at the Maker Lab: faulty door stops. Thinking of all the times students were locked outside the classroom, We challenged ourselves in creating a device that would efficiently ajar the door. With a very complex previous prototype, Team Supra was inclined to develop a resounding solution in a simplistic way. We realized that simplicity yielded easy constructability, low costs, and room for continuous improvement without drastically increasing the price.

We began by taking time to understand and explore the market. It became evident that the vast majority of doorstoppers sold between $5 – 15 (with premium stoppers above $20) and were all made of rubber material. Team Supra also met with Fab Lab to gain criticism on our idea. Fab Lab recommended a product with some form of a base that could attach to the door near the door knob with some form of a sliding mechanism that would allow for the locking position to turn “on and off”. While Team Supra initially hypothesized utilizing magnets to attach our device to the door, Fab Lab’s expertise made it evident that no household friendly magnets would be strong enough to sustain the impact of the door. Additionally, Fab Lab recommended the employment of a wood coated in rubber resin or semi flex material for the actual stopping block portion of our product.

Prototype One

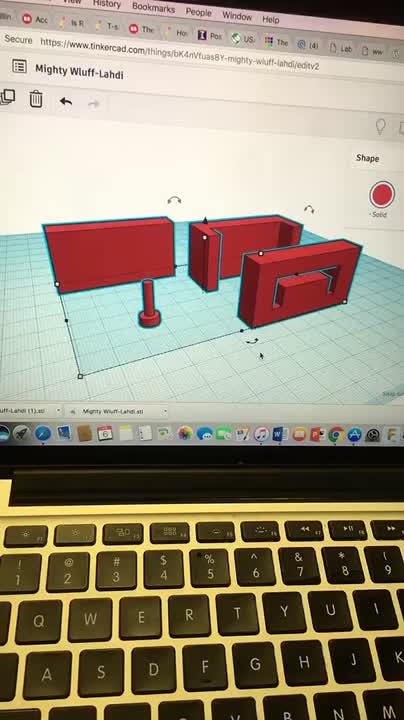

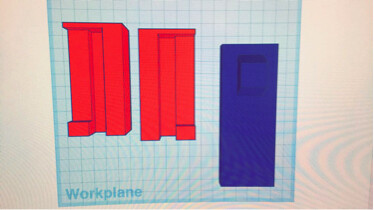

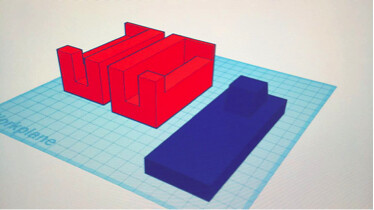

Using TinkerCad, Team Supra was able to create the following prototype:

From our first prototype, we realized we really liked the shape of the base and the handle attached to the base. The handle allowed consumers to easily slide our product from “on to off” and the base could hold our “stopping block”. However, we realized that our first prototype had nothing to prevent the sliding piece from detaching from the base and was too small and brittle ultimately resulting in breakage during testing.

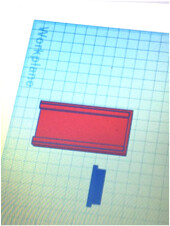

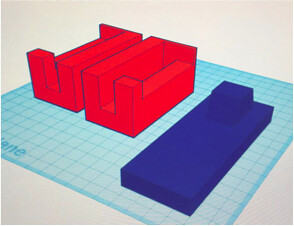

Prototype Two

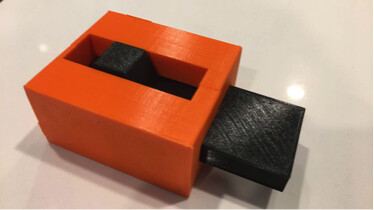

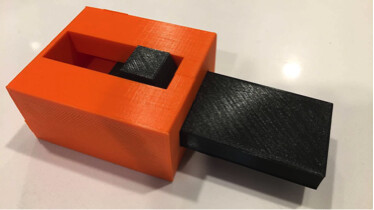

After analyzing our results of prototype one, we decided to increase the surface area, density of base & block, and overall thickness of our prototype. Additionally, we added a bar to prevent the block from sliding out. And here is a video demonstrating progressive success from our prototype:

After achieving progression, Team Supra decided to perform testing to reaffirm the consumer need for our product and also verify the usability and ergonomics of our product.

Quality Assurance and Consumer Testing

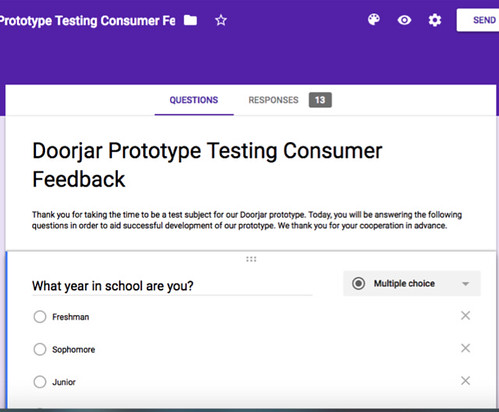

Using google forms, we created a consumer experience feedback survey to be completed after the consumer had personally experienced and utilized our prototype two.

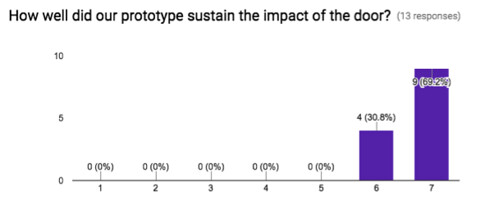

Our survey questions centered around the following topics: demographic information, problem solutioning, aesthetics, ergonomics, applicability, durability, and willingness to purchase. Additionally, we realized the necessity in random sampling and ensured our sample had participants of all different years, majors, and household incomes in school. And, our key consumer insights were as follows:

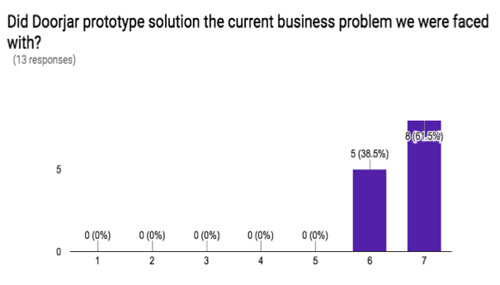

From a scale of Not At All(1) to Absolutely(7), it becomes evident that our whole sample agreed that our prototype solution solved the current business problem.

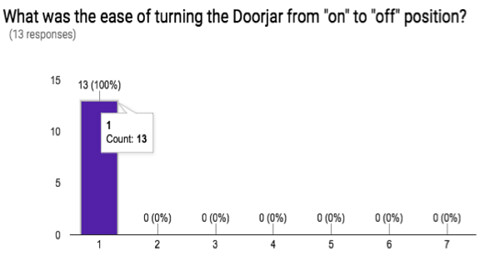

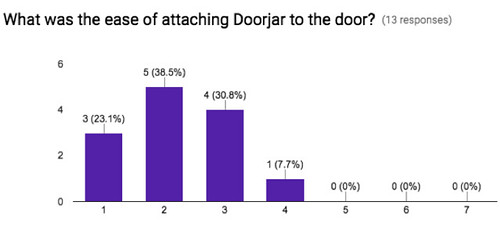

Additionally, we saw that overall our product was relative easy to use, but there was an opportunity to enhance the attachment experience.

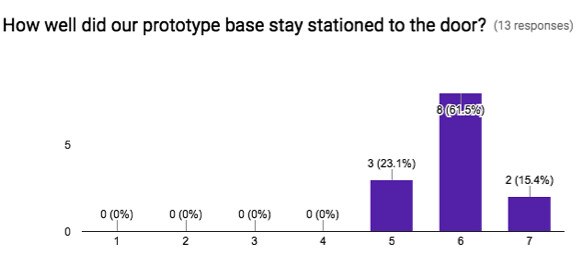

Our participants believed that our prototype could sustain impact from the door as and stay stationary. However, we did see a small discrepancy in Doorjar’s impact sustainability and impact stability (or stationing capability) and realized keeping the prototype base stationed to the door could be an area of improvement.

Lastly, our results show that our subject participants were relatively happy with our product and most were relatively willing to purchase our product at an average price of $7.73.

Prototype 3

In our final prototype, we made the base material out of PLA, printed the block material out of semi-flex, and printed it with a 40% infill. And our final product proved to be even more successful than the previous attempt.

Next Steps & Time Constraints

With only 8 weeks, we were forced to stop our prototyping efforts and prepare for our final presentation and wrap up for this class. However, had we had more time we would have pursued four additional features. Team Supra would have potentially utilized clear plastic or acrylic to enhance aesthetic appeal for Doorjar. Dual functionality would be added giving DoorJar both ajaring and locking functionality. Bluetooth functionality would have been implemented alerting consumers when their doors are fully locked and open and some unique attachments could also have been added to the door.

In terms of bringing DoorJar to market, Team Supra did some due diligence and was able to prove profitability margin of 23.35% with Doorjar. This was derived from a $5.94 cost per unit (PLA and SemiFlex material costs researched and labor, utilities, and building costs estimated) and a $7.75 retail price that was proven through our feedback survey. Lastly, Team Supra segmented its implementation plan into 4 unique categories. Initial Capital Investment would seek funding for our project in order to purchase 3D equipment, hire employees, and pay building costs. Relationship Development with Suppliers would ensure low raw material prices and overall low costs for the product. Commercialization begins the creation of our product seeking for opportunities to cut process inefficiencies, cycle flow time, and identify bottlenecks within the process. Marketing & Sales ensures awareness of the our product and that Doorjar remains successful with a loyal consumer base being relentless built.

Hi Team Supra,

Throughout the class I had watched as your idea evolved and your final product turned out to be great for your target consumer and when the product was passed around the class during the final presentation it was incredibly sturdy! I liked the testing video, it really showed how the future user could use the product and how it was strong enough to handle impact. Furthermore, the analysis you had provided from possible college consumers was very insightful, especially in finding the perfect pricing. I hope the three of you had a great experience in creating your product together and may take away the knowledge from the creation and the course to your future endeavors!