The curation of our idea from concept to prototypes to fulfilling the design requirements has been a journey. With that being said, our product contains a lot of parts and materials to come together, from acrylic from the Fab Lab to 3D printing at the Makerlab, to clay pebbles and then lastly a fish. Our project combines technology and biology to form a symbiotic balance and that is where some issues may arise.

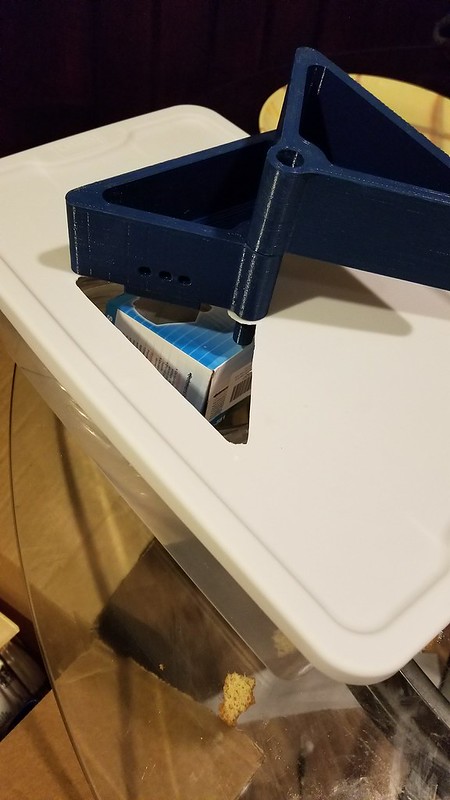

We received some great constructive feedback this week with a design audit partnered with another group and from there we determined that an increased in depth to the modules will allow for healthier plants overall.

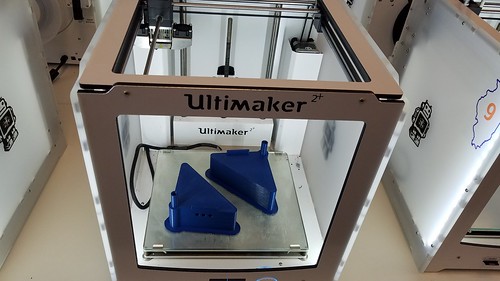

This week we were finally able to use the 1/4″ x 12 x 24 sheets of clear acrylic that we will be making our fish tank from scratch with silicone sealants as well. After some trials and errors with the laser cutter, we were finally able to cut everything to size but fear it will not be cured in time for the prototype review with Vishal on Monday. With that being said, our next hiccup came from the 3D printers failing to complete our prints in a timely manner. This week we encountered our 2nd failed print and each of our prints take 10 hours and so time is of the essence when it comes to creating the aquaponics modules. Our team has been working tirelessly when it comes to designing and putting together this product. With the help from the Fab Lab and the Makerlab, we are slowly able to achieve our vision.

There are hiccups along the way but we know we will be able to complete this in due time, but we constantly remind ourselves that Rome was not built in one day and for us to deliver our product we have to realize that an attention to detail is essential.

Our next phase of achieving our vision is putting the fish tank together with the use of the 1/4″ clear acrylic sheets and aquarium approved silicone sealant to ensure that the tank is waterproof. Due to scheduling conflicts and the allowable time for the tank to cure we were not able to complete the tank on time due for the class for Vishal’s review of our model. However, we were able to use a simple plastic bin to simulate our tank until we have it finished during the final presentations. This week proved to be a difficult week for us due to the complicated nature of the project and how many pieces are coming together. But we were able to reprint our modules to ensure that it is of the top most quality. Our project has been a test of many moving parts and the culmination of it coming together is very exciting but also nerve racking as our goal is to have our product 100% ready within the week.

Hey Kenny,

I’m glad your project is coming along! Well finished at this point! Glad you guys were creative enough to jump over all the hurdles you guys face.Can’t wait to see your final presentation on Monday!

Great post. I find that when our group runs into the biggest obstacles with our product, when we develop a solution is when we get the most creative. I also like the saying Rome was not built in a day. With projects like these the constant testing and adjustments to prototypes can be frustrating. Even so it is these adjustments that make the projects better. Looking forward to hearing your presentation!

Love the title. Your updates are always so detailed and intuitive. A reader can really know what you’re group is up to. Both prints look great. Even if the first batch didn’t turn out too well, they at least let you know about ways to maybe improve the design and things to look out for during assembly. Rome definitely wasn’t built in a day, but yours looks like it’s turning out fantastic.