How to… 3D Scanning (This post)

.

3D Scanning… What is it? As the name says, its the scanning of a 3D object, and can be done with fairly basic technology. It works through the process of laser triangulation, using a sensor to pick up reflected laser rays.

.

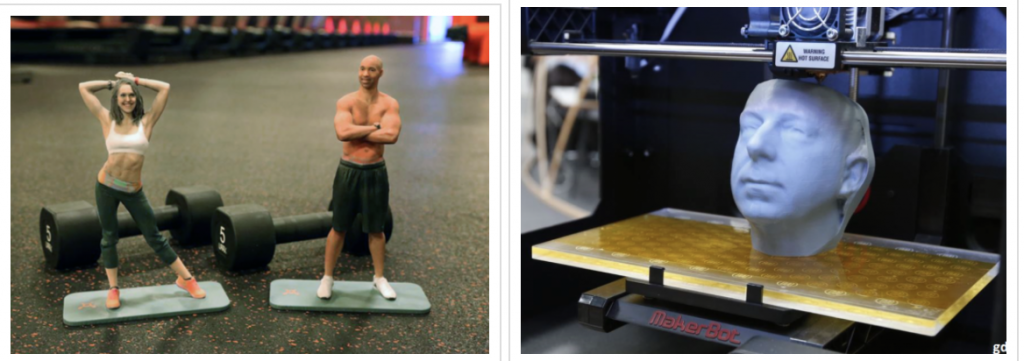

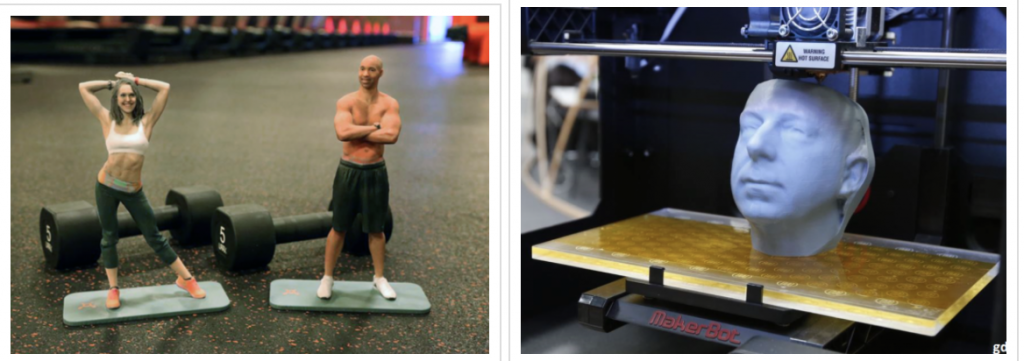

Its very popular commercially as personalised gifts: busts or even whole bodies can be scanned and printed.

Printing in different materials even allows for different colours to be printed on a model

.

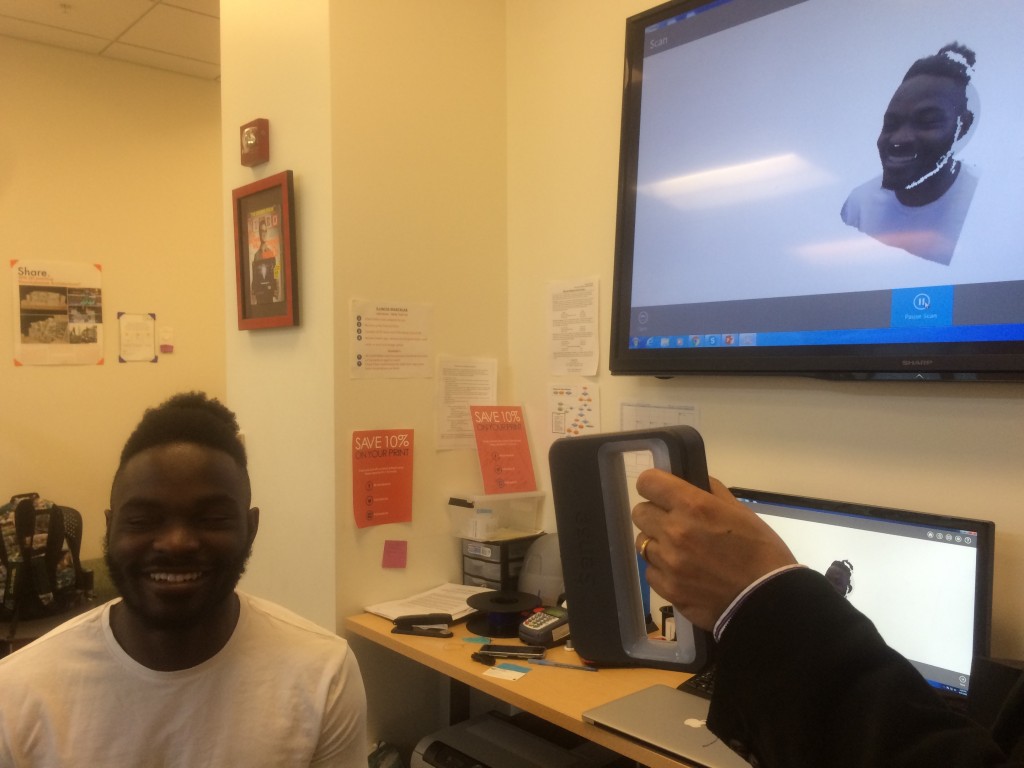

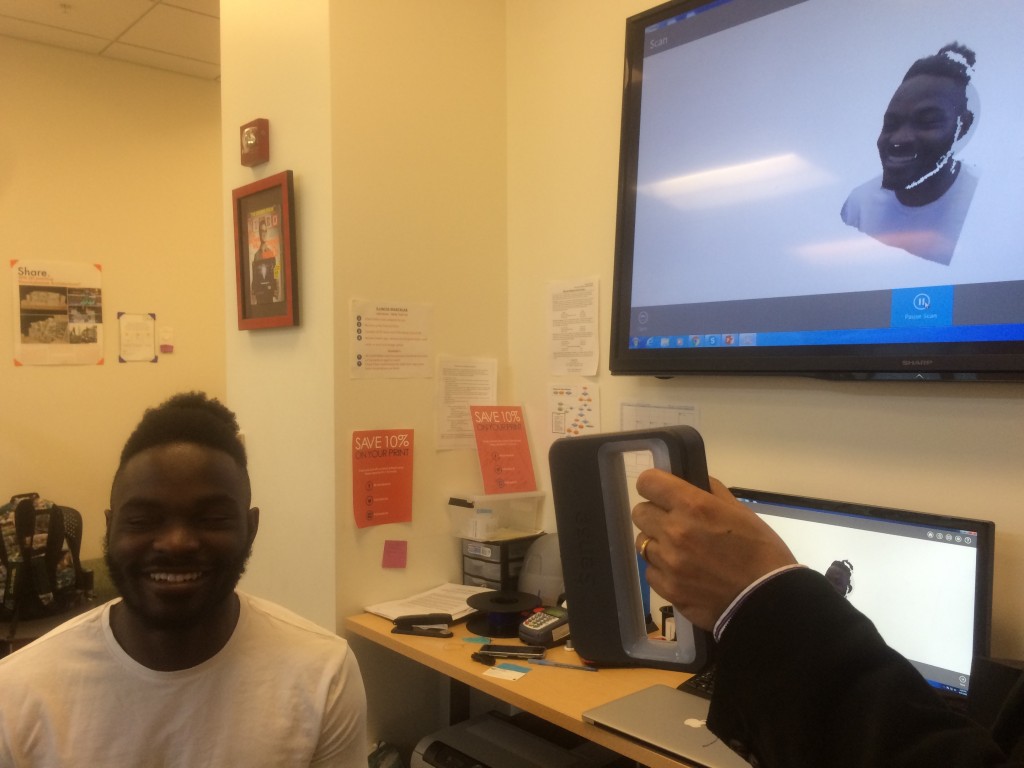

Simple camera attachements like this iSense scanner can be added on to existing technology to create the scan.

Here 3d scanning has been utilised in a novel way to produce a quirky iPad stand.

More expensive scanning devices do also exist, with more accurate laser and sensing technology for finer detail scans.

.

General workflow for producing a 3D print from a 3D scan:

- scan in image*

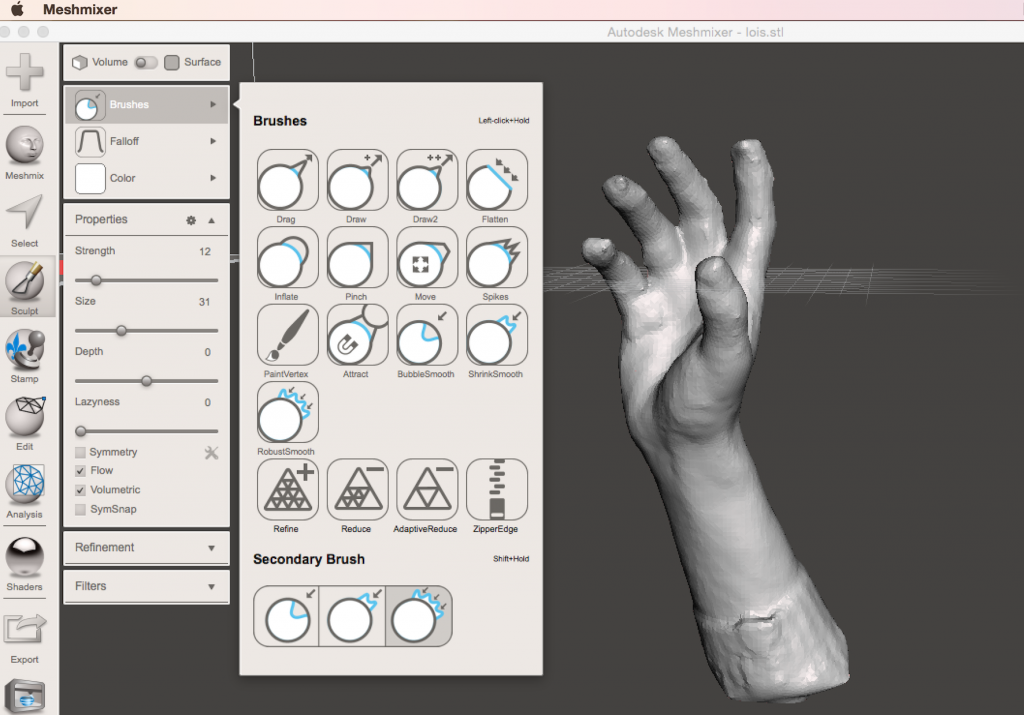

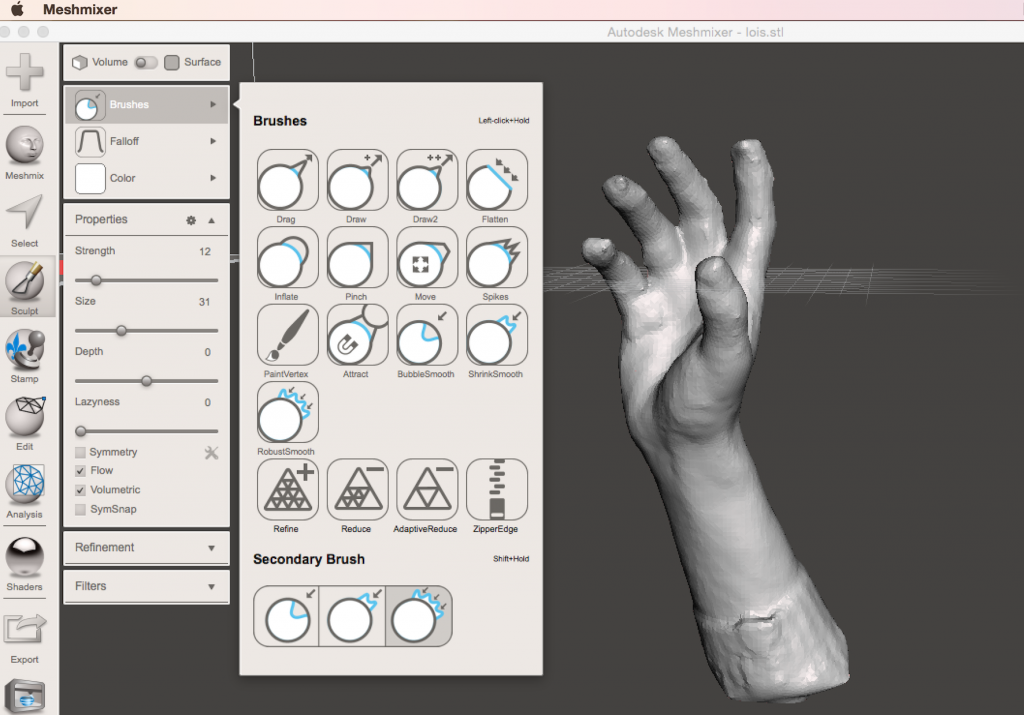

- using Autodesk Meshmixer to clean and tidy up the scan, scale image to sit on the dimensioned printing bed

- use edit and sculpt functions to smooth out blemishes on the scan (e.g. smoothing out hair on a bust)

- Add a base for the print by selecting from primitive shapes

- autorepair under the analysis inspector section, to fill in any holes on the scan

- combine all shapes, and save as an .stl file to be imported into Cura for printing

*scanning the image is the hard part! Very easy for the scanner to “lose track” of the object

For this exercise, I wanted to create something functional from my 3D-scanning. Scanning a bust is a very common use of basic 3d scanning, so I wanted to experiment with a more challenging scan.

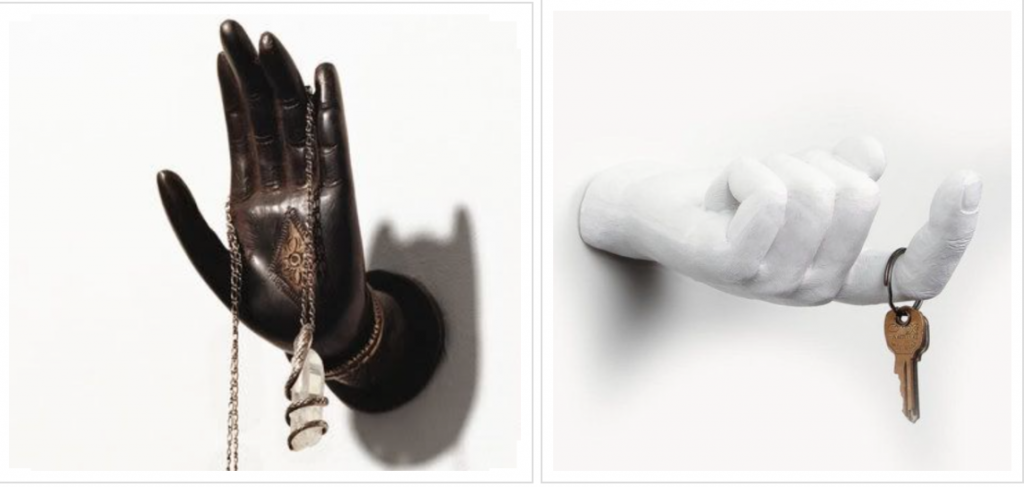

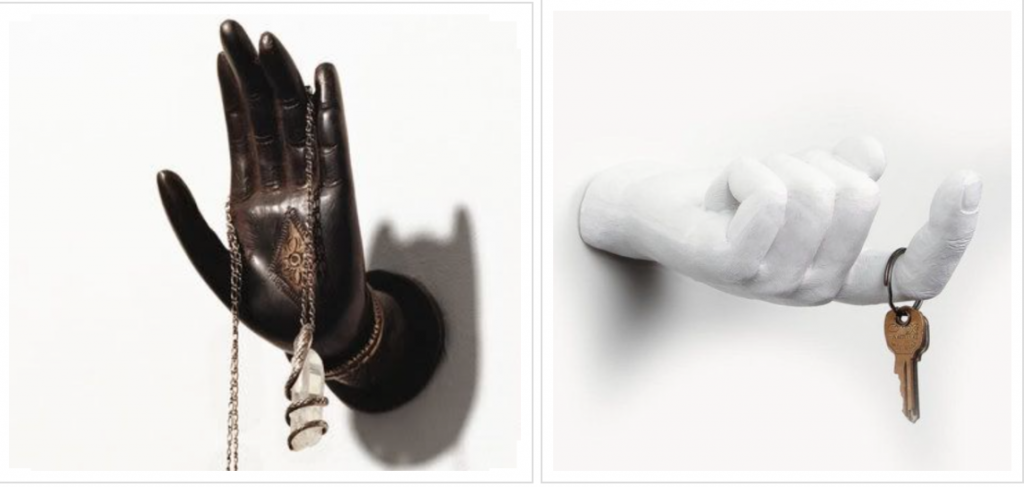

My aim was to scan a outstretched hand and arm, with the goal of turning it into a unique and customised coat-hook or key-holder, like these:

I want to create something like this, using 3D scanning

Since busts are a common use for 3D scanning, the software we were using had algorithms written in to be able to pick out the head shape for a scan, and has optimisations in place to pick up the head scan as smoothly as possible.

Building up a scan image by rotating head and shoulders on a spinning chair

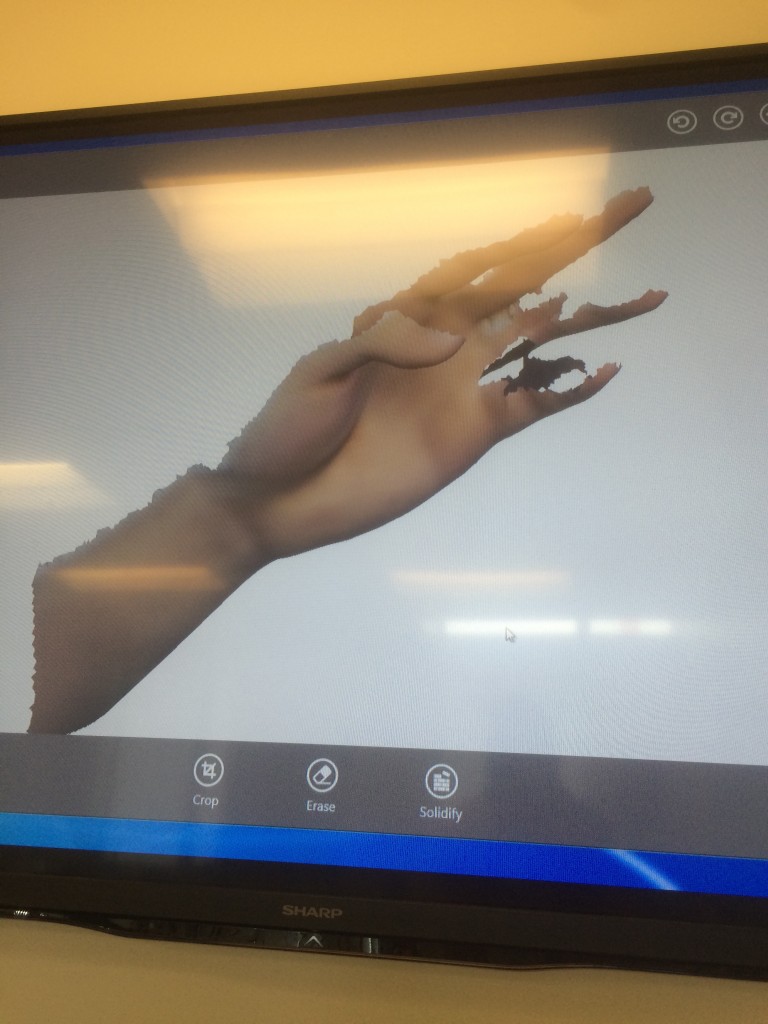

A particular challenge was getting the scan software to recognise the hand as the item to scan, and not everything else in the background.

Once the scan started picking up the hand as my object, the difficulty was in rotating the scan-camera round the hand to get a full 3D image. It works well for a bust because when sitting on a chair, the rotation has the head at the centre of the axis. I found it very difficult to have the centre of the scan object at the centre of rotation. Its hard to rotate an arm about the same spot!

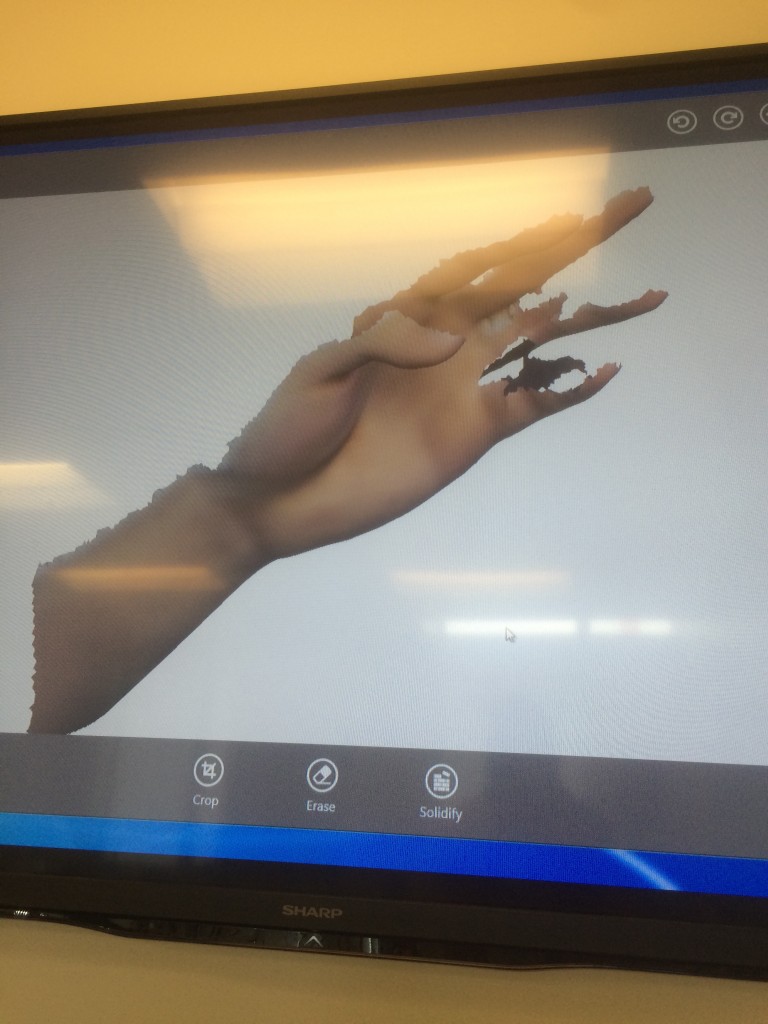

There were many failed scans that looked similar to this:

Many scans later there was a better one that was incomplete, but had enough framework in place that I could then build up the missing parts of the hand using Meshmixer.

After some editing and little fixes (recreated and extended some fingers!), I managed to create this:

It worked! 3d printed hand scan

(return to main navigation menu)

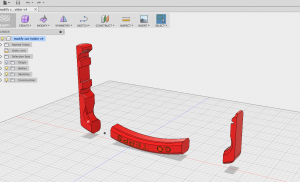

. Josh and I wanted to incorporate multiple aspects into the design to show off our skills we learned this semester, this being the reason for the rastering of the side. That, and it looks pretty cool 🙂 We also had to make a change to the fish head so that it would fit on the tuning peg without breaking it so we made some edits in Fusion and re-printed the new piece.

. Josh and I wanted to incorporate multiple aspects into the design to show off our skills we learned this semester, this being the reason for the rastering of the side. That, and it looks pretty cool 🙂 We also had to make a change to the fish head so that it would fit on the tuning peg without breaking it so we made some edits in Fusion and re-printed the new piece.

![IMG_1640[1]](http://publish.illinois.edu/digitalmaking2016/files/2016/04/IMG_16401-225x300.jpg)

![IMG_1641[1]](http://publish.illinois.edu/digitalmaking2016/files/2016/04/IMG_16411-300x225.jpg)