Time for a new software! In the past few weeks, we’ve been going through a new software (well, new to us) that can be used in designing 3D items – Fusion 360!

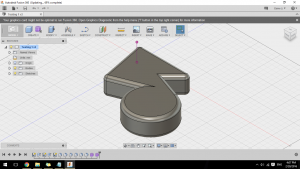

We started out learning all the basic functions of F360, how to ultilize the commands and all that jazz. Since we were essentially freeforming, here’s a pic of the slightly off shape I ended the lesson with:

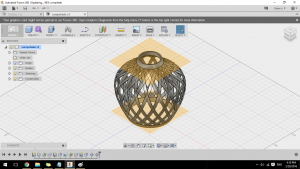

After that for our weekly assignment we had to follow one of the tutorials posted on the Autodesk website and create something from there. Honestly, it wasn’t as easy as I imagined it to be. After all, we’re following something step by step! There were a couple of times when I ended up in the wrong environment and couldn’t find a specific tool that I needed, and other times when I just clicked on random buttons and couldn’t go back, so I guess this practice was a great one to familiarize ourselves with the program.

Anyway! I created a lampshade from the tutorial, which was awesome fun.

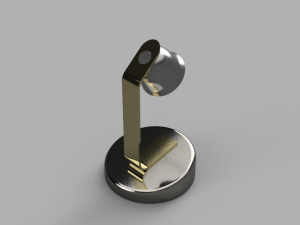

During class on Monday, we were supposed to design a desk lamp (which mine ended up turning wonky at the very last few steps to connect the lampshade and the arm). One of the really cool things about Fusion 360 is that we get to pick what materials we would like our lamp to be rendered into, and I ended up picking platinum for the base, gold for the arm and silver for the lampshade, which was utterly unfeasible, but still really cool. Look at how shiny that is!

Now that I know a bit of the basics, I can’t wait to create more stuff and print them!