This week was a work week for everyone. We spent our time making some progress on the many individual and group projects going on for the end of the semester.

Group Semester Project

I talked with my group formed from an event called the Make-a-thon that happened last weekend. We are planning to continue the project past the scope of the event. Here is an explanation of where we are at this point:

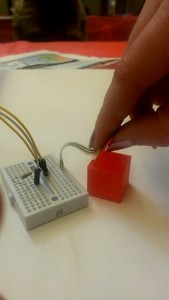

During the Make-a-thon we came up with the idea to have a pill box hooked up to an arduino that could sense when you take the pills out. The goals was to set up some kind of alarm system that would alert the user when to take their pills.

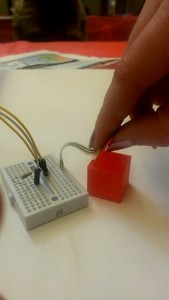

We ended up with a semi-working prototype that included a pressure sensor. We had the sensor working perfectly with some simple coding. And we decided to quickly 3D print a small box to represent one of the days of a 7-day pill box.

Here’s what our prototype looked like:

Not too fancy, but we liked the idea and learned a lot during the event.

Not too fancy, but we liked the idea and learned a lot during the event.

Since we didn’t stay overnight at the Make-a-thon we didn’t go into detail how the alarm system would be hooked up. We had the readings from the pressure sensor coming in, but we didn’t know how to send that information anywhere to make an alarm.

We are looking to update our prototype in the coming weeks by making a complete 7-day pill box and trying out multiple light sensors since we were limited to only the one pressure sensor. We may even laser cut a press fit pill box, but we are faced with a bit of a challenge with the lid. Watch out for future posts to see where we end up with our idea!

Individual Semester Activity

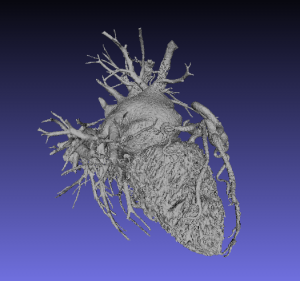

This week I also worked a bit on my individual semester activity. Over the past few weeks I have been learning about converting medical data such as CT scans or MRIs into a 3D printed object. I have run into a lot of problems, but I have learned so much.

The coolest thing I learned was that there is a community of people out there that do this already. It’s a small community, but what they have done so far is amazing. Here is a website I found where they share their files, write blog posts, and answer questions in a forum regarding anything to do with biomedical 3D printing: http://www.embodi3d.com

Something I have noticed from my research is that the files I need are very rare. Medical data is not readily available to the public. I have asked around and searched all around the depths of the internet, but everything I have stumbled across is too complex or just not what I’m looking for.

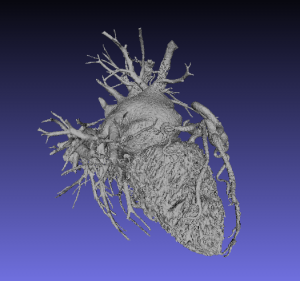

Also, I was hoping to work with a human heart scan, but every file I have tried to edit has been impossible to get to a printable state. Here’s the closest I got:

And this was after a long process of cleaning! So, you can tell that this is not an easy task.

At this point I am either going to print one of the ready-to-print files from the biomedical website or switch over to another body part…basically anything but a heart.

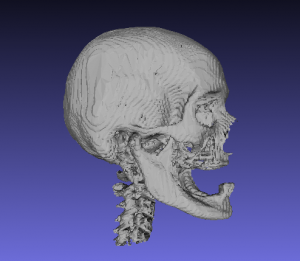

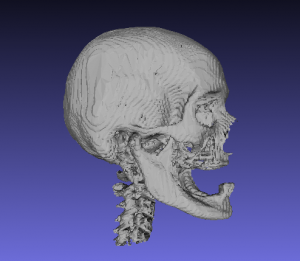

When I first was learning how to edit files I tried out a skull, which was super easy and probably was printable with a bit more editing. Here’s that file:

Bones are much easier to work with! I knew that a heart would be a challenge, but it was way more than that. It was a nightmare!

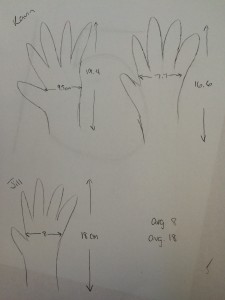

I’m going to play around with files from a friend’s MRI scan later this week and see if I can work with her data. I am super excited that she is allowing me to use her MRI and I hope I can print her something! She’s a medical student, so she would love to have a 3D print of her brain. We’re both super excited to see what I can do! So be sure to keep an eye out for any progress with this project.