This week we were originally be going to do a collaborative showcase of our work with the Making Things class in the BIF, but last minute we decided to push our portion of the showcase back so we could have more time to prepare and show off more of what we’ve worked on in class by holding it at the end of the semester. Instead of scrambling to get everything done for the showcase then, we had “free time” in the lab to work on our semester projects. Sam and I worked on assembling our second Raptor hand (an all white one this time) and looking for places we could source the materials from instead of having to buy a full kit each time. Putting the hand together this time was a bit faster than the last since we knew what we were doing and had the tricks figured out for the tougher parts (file down the pieces if you can’t fit them together, use a safety pin to get the elastic through the holes, etc.)

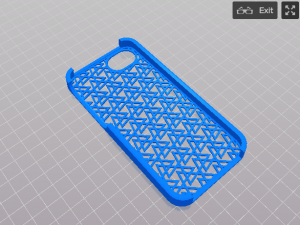

Since its hard to have two people work on the hand at once, Sam mostly worked on assembly, while I looked for places to buy the materials for future hands from. Most of the stuff was pretty easy to find on Amazon, except for the screws which I will probably look for at a local hardware store. Since finding materials didn’t take too long, I had some time at the end of class to check out Thingiverse play around with 3D modeling and ended up using the MakerBot Customizer tool to design and print a new case for my iPhone. I printed it out in white plastic on the Generator and I’ve been enjoying showing it off to my friends the past few days.

I did the same thing when I printed a phone case over a year ago. Although, I was too afraid to actually use mine because it was too cool to risk breaking. I guess I could print another one now.