RESEARCH

Scientific Challenges

- High Dynamicity – Due to the dynamic nature of the complex system, the chiller plants in operation are never in a stable status. Even with exactly the same configuration, with the varying external conditions, e.g. weather, and internal conditions, e.g. human activities, the chiller plant may face dramatic changes on the running status and operation feedbacks.

- Long Response Latency – Chiller plants respond slowly to updates on the configurations. Such property brings two difficulties for automatic optimization systems. Firstly, the observations on the chiller plants at present time are consequences of previous operations minutes ago. Secondly, the expected performance of new operation cannot be verified immediately.

- Real-time Constraint – To run the automatic chiller plant optimization system online, it is crucial for the system to run optimization computation efficiently, to support fast response to updates from the building.

- Poor Adaptivity – Different chiller plants have very different characteristics. The variance stems from the huge difference on the specification of the chiller plants, such as the number of chillers, the connectivity of the pipes and layout of the building. Such property makes it extremely difficult to reuse successful setup from an old building on a new building.

- Hardness of Evaluation – It is nearly impossible to validate the optimality of chiller plant configuration, because of the hardness of finding optimal solution to non-convex optimization problem. Furthermore, it is also challenging to evaluate the effectiveness of a particular tuning approach against others, for either manual tuning or automatic tuning, since the external conditions are hardly repeatable. A well performing tuning strategy, for example, could be the result of temporary good weather.

Methodologies

To tackle the technical challenges listed above, we plan to design a new-generation automatic chiller plant optimization. In Fig. 2, we present the architecture design of our new system. Generally speaking, the system consists of an online running component at chiller plant site, and an offline component running on cloud platform. The online component is directly connected to the chiller plant for data collection and control, together with an interface to building managers and onsite engineers. The offline component mainly runs on the cloud, with data management and learning modules running with external knowledge from domain experts or Internet.

Figure 2: The interaction with chiller plants, engineers, administrator and external information source.

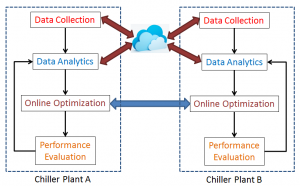

The processing modules within the automatic optimization system follow the general workflow in Fig. 4. There are four core components of the optimization system, including the data collection component, the data analytics component, the online optimization component and performance evaluation component. The data collection component is responsible for sensor data preprocessing, especially on cleaning meaningless records. The data Analytics component builds models to understand the dynamics of a chiller plant, based on historical data collected and stored the cloud platform. The online optimization component runs algorithms to find optimal configuration of the chiller plant in real-time. The performance evaluation component estimates the optimality of the model and optimization algorithm, with the results fed back to the data analytical component for model improvement. The data collection and data analytics components utilize cloud computing technique, so that different chiller plants share the storage and computation resource on cloud for cheaper operation cost of the systems.

Figure 3: The general framework of the target optimization system for chiller plants.

We adopt the following technologies to address the challenges in the components, in order to improve the efficiency of chiller plants.

- Data Cleaning on Chiller Plant Readings – The sensor readings from chiller plants are error-prone. Typical problems, including missing values and out-of-range errors, are mainly due to the limited accuracy on the measurements and temporary faults on the sensors or network connection. To minimize the negative impact by the poor readings, it is important to design a systematic approach to identify and remove the records, before sending the data to the data analytics component. To accomplish this goal, we will build new data cleaning tools, which can find outlier patterns in the data and eliminate by an interaction interface with domain experts.

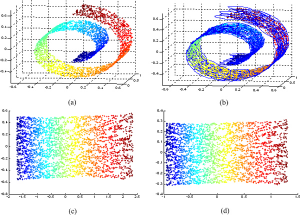

- Non-convex optimization over objective manifold – Chiller controlling is known as a high-dimensional optimization problem with non-convex objective on energy consumption. Motivated by the general research on manifold [TSL00], as illustrated in Fig. 4, we propose to unfold the manifold to a lower-dimensional space, such that the observations on the chiller plants are uniformly distributed in the new space after mapping. Such mapping enables the optimization algorithm to more effectively search plausible solutions and identify similar cases in the database. It also facilitates much better optimization efficiency, since most of the search is done in the low-dimensional space.

Figure 4 [TSL00]: Manifold unfolding conducts a non-linear transformation from original high-dimension space into a low-dimensional space with almost uniform distribution.

- Adaptivity by transfer learning – Transfer learning [PY10] is the best candidate information technology to enable partial knowledge transfer when there are similar but slightly different domains, e.g. chiller brands, to investigate at the same time. Specifically, by applying transfer learning, the learning system identifies common features in the deep neural network and aligns the features across different chiller plants. For instance, although different chiller plant may employ different controlling parameters, the underlying mechanical rule is exactly the same. Transfer learning is expected to find these features and utilizes the features when tuning on new chiller plants with limited observation data.

- Real-time optimization with multi-core computation architecture: While the computation resource on the cloud platform is virtually unlimited, the computation power on the workstation of the chiller plant control system is highly limited. Given the deep learning model output from the cloud platform, the workstation in the server room on the chiller plant site is responsible to run real-time optimization on set points, in order to respond to the varying condition of the chiller plant. Despite of the limited computation power of the workstation, new generation of workstations usually are equipped with multi-core CPUs. It is thus possible to apply generic parallel optimization programming, in order to exploit the CPU cycles of the cores.Furthermore, we also would like to explore the idea of search space minimization, by exploiting the domain knowledge available to the system. In particular, there are a number of successful cases on performance modeling of sub-systems in chiller plants, e.g. the air fan and the pump, to achieve optimal efficiency. These models can be integrated into the real-time engine, in order to minimize the efforts used to search in the large parameter space. To accomplish the goal, we need to generate generic rules to transform the domain knowledge into codes usable by the optimization engine.

- Performance Evaluation: Evaluation is the key component to the automatic optimization system, which controls the iterative improvement of automatic tuning system based on the evaluation outcomes on previous configurations on the chiller plant. The goal of the evaluation is to understand the wellness of an automatic tuning strategy, especially when compared against other strategies. When these strategies are run on different days, the performance not only depends on the optimality of the configuration, but also on the external conditions, e.g. weather, humidity, etc. Under completely different conditions, it is nearly impossible to conduct fair comparison between the strategies of chiller plants. To eliminate the impact of varying external conditions, we will apply new normalization techniques on the efficiency results of the chiller plants.Basically, given the large database of chiller plant historical readings, our system automatically finds hours with most similar external weather conditions and building cooling tonnage. The efficiency of the new strategy is then compared against the old readings on these similar hours. This allows meaningful statistical comparison of the current kW/RT against historical kW/RT with similar external weather conditions and building cooling tonnage. This scheme needs supports from data management component of the system with highly efficient search functionality to retrieve the similar hours that to generate statistically meaningful results.

References

[TSL00] J. B. Tenenbaum, V. De Silva, J. C. Langford, A Global Geometric Framework for Nonlinear Dimensionality Reduction, Science 290(5500): 2319-2323, 2000.

[PY10] S. J. Pan, Q. Yang, A Survey on Transfer Learning, IEEE Transaction on Knowledge and Data Engineering, 22(10), 1345-1359, 2010.