HOME

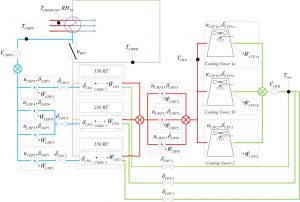

Chiller optimization is one of the most crucial problems to smart building systems, as the energy consumption of chiller plant comprises over 40% of the total energy consumption of a modern building. Poor efficiency is commonly observed in existing chiller plant systems, due to the excessive overhead and technical hardness of manual tuning. In practice, a large number of chiller plants and buildings are optimized during the first few months in operation, when experienced engineers spend huge efforts on fine-tuning the chiller plants to achieve near-optimal performance. However, the efficiency of these chiller plants deteriorates quickly when the engineers with expertise leave the projects, such that the configuration of the chiller plant does not respond to the varying environment. A fully optimized chiller plant usually runs at excellent efficiency during office hours, but performs poorly at nights/weekends/public holidays. To the best of our knowledge, even large multinational companies do not have 24-hour engineering support to chiller plants with manual monitoring and control. Moreover, even veteran in the industry may not always make correct decisions on chiller plant optimization. The extremely high complexity of chiller plants (as illustrated in Figure 1) often leads to ineffectiveness of conventional tuning tricks used by the engineers. The best engineers may only tune the chiller plant system in a trial-and-error fashion, trying to understand the chiller plants with their experience and sometimes simply heuristics.

Figure 1: Schematic of chiller plants in a building, which includes temperature measurements, T, a relative humidity measurement, RH, continuous input variables, u, binary input variables, δ, and power consumption measurements, W ̇.

It is thus highly appealing to develop an advanced chiller plant optimization and data management platform that can be easily applied on different buildings, with minimal requirements on experience and efforts from the building managers. Unfortunately, there is no existing successful system in the industry so far, to achieve optimal efficiency by automatic tuning. There are a number of technical difficulties underlying the problem of automatic chiller plant optimization. Firstly, the chiller plant is such a complex system that efficiency tuning is simply a non-convex optimization problem in terms of the controlling parameters. Secondly, the performance and service quality of chiller plant depends not only on the controls over the devices, but also on the external factors, such as weather condition, human activities, occupant density and aging equipment. Thirdly, different buildings may have completely different characteristics, leading to hardness to transform successful experience from one building to others. All these challenges make it extremely difficult for computers to model, evaluate and optimize the efficiency of chiller plants.

With the recent advances on deep learning and explosive growth of computation power by cloud computing, it is the right time to apply sophisticated machine learning techniques on chiller plants to reshape the landscape of automatic control for energy saving. In this project, we aim to design a novel platform to optimize the coefficient of performance over 24 hours, by utilizing new automatic chiller plant optimization. The research focuses on the automatic optimization feature of the platform with i) automatic optimization strategy, ii) a feedback system to evaluate effectiveness of the optimization strategy, iii) a deep learning system to learn to adapt the more effective optimization strategy (and discard inferior optimization strategy), iv) to support real time and dynamic control over chiller plants in response to the status change of the building. We propose to solve all these problems by building an industry-level automatic optimization platform, incorporating state-of-the-art data processing, machine learning and human-computer interaction technologies.