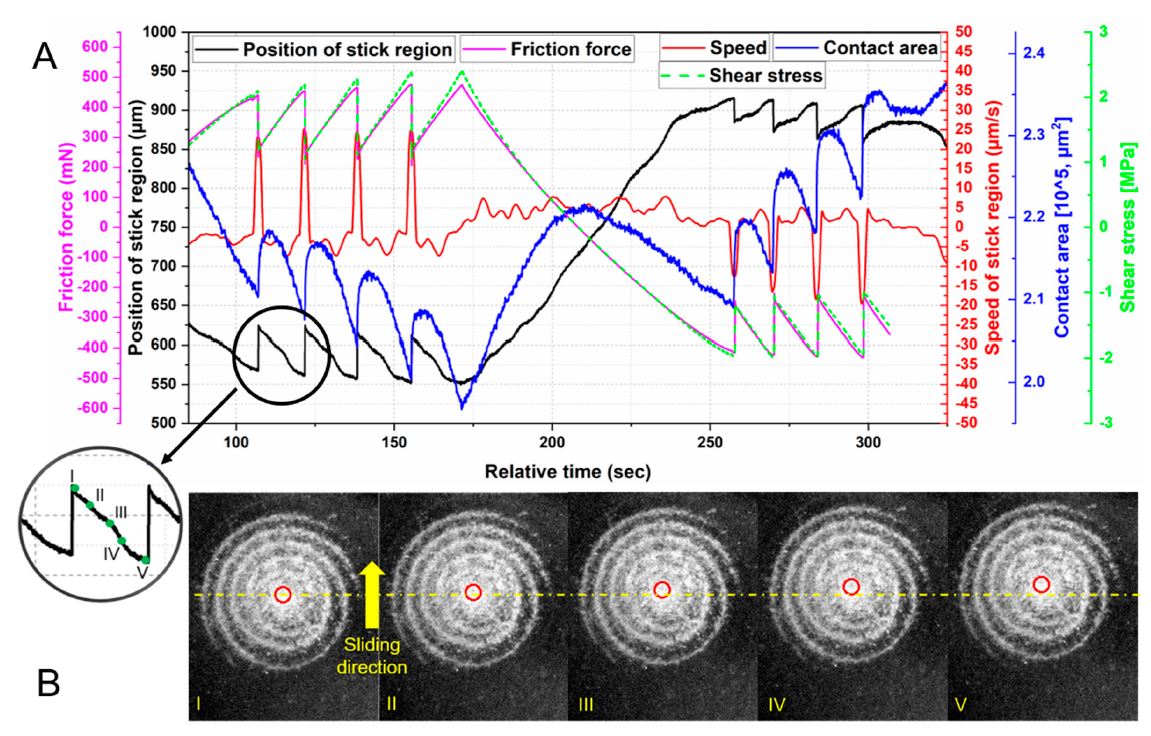

His work is published in this new paper, in which he carefully mapped the evolving contact area during multiple stick-slip events which were elicited under a wide range of driving lateral speeds. Similar to sliding a finger over clean glass, an elastomer won’t slip very evenly, but rather undergo a series of stops and starts where it sticks briefly, then slips, then sticks again. This is called stick-slip friction.

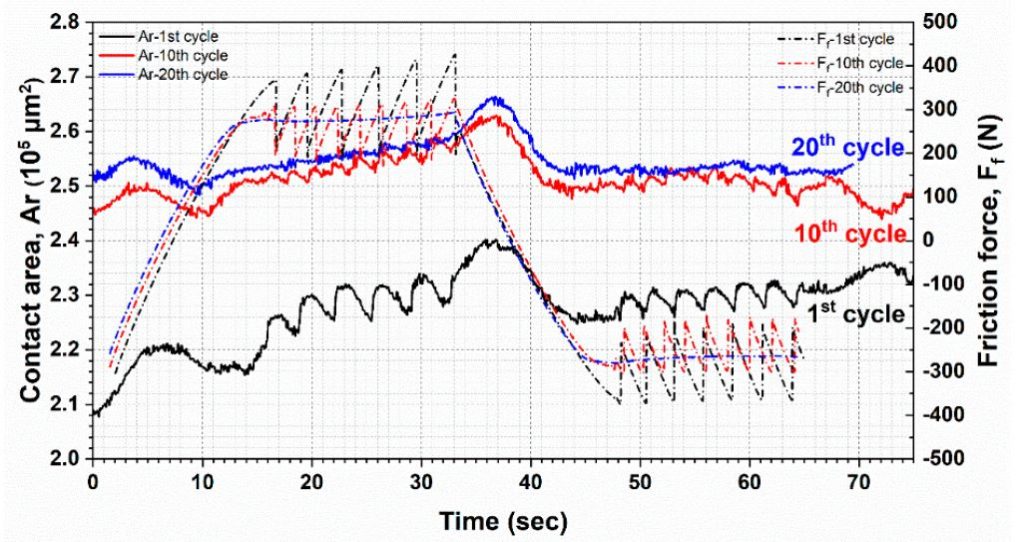

From contact of adhesive contacts between metals, we know that when you push an object sideways, the area of contact grows slightly, also called junction growth. That makes sense all the way up until you push the object so hard that it slips! When it slips, the area of contact must decrease. So when it’s stuck and hasn’t slipped yet, how can the area both increase AND decrease? Well we find for the first time that it undergoes a parabolic trend of first increasing, then decreasing, with every stick event. This can be thought of as a competition between the amount it wants to stay stuck (adhesion), and the most the surface can stretch before it has to let go. It’s a tug-of-war where each effect wins in an alternating fashion. Read our paper for more details!

https://www.mdpi.com/1996-1944/13/20/4615