|

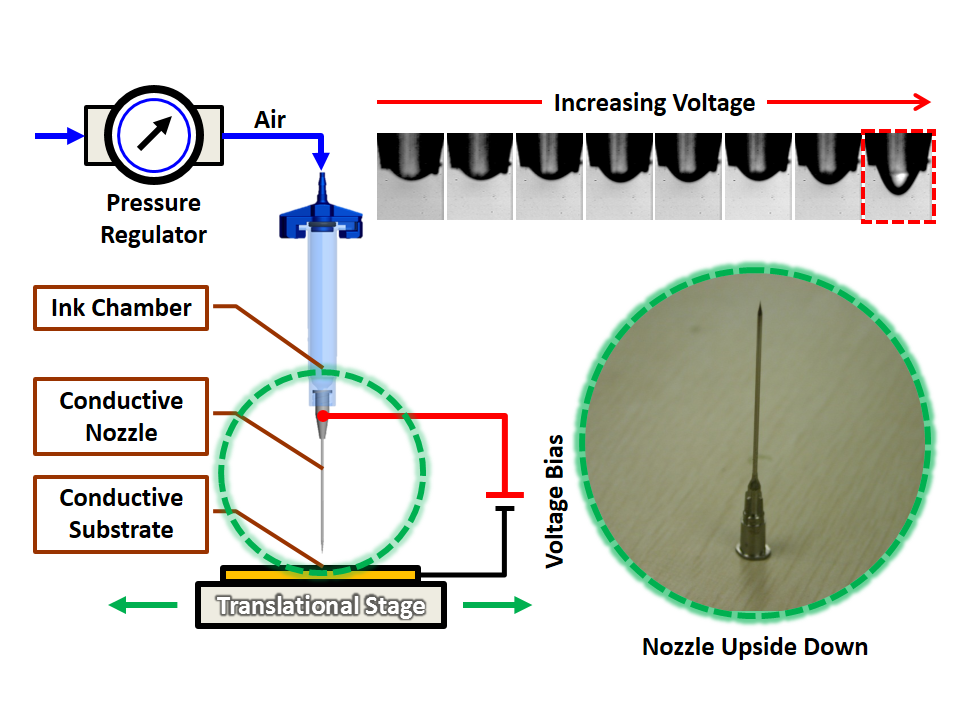

ELECTROHYDRODYNAMIC-JET PRINTING Nano and micro-manufacturing has emerged as a critical component of nano and micro systems technology. Along with an increasing variety of available materials comes a need for increasingly sophisticated manufacturing platforms capable of utilizing said materials at higher and higher levels of resolution. Electrohydrodynamic jet (E-jet) printing uses an electric field to induce fluid flows from micro capillary nozzles to create devices in the micro/nano-scale range.The figure below presents the basic components of an E-jet printer and the video showcases the camera view (10x) of the E-Jet printing process in real time fashion. |

|||||

|

|||||

|

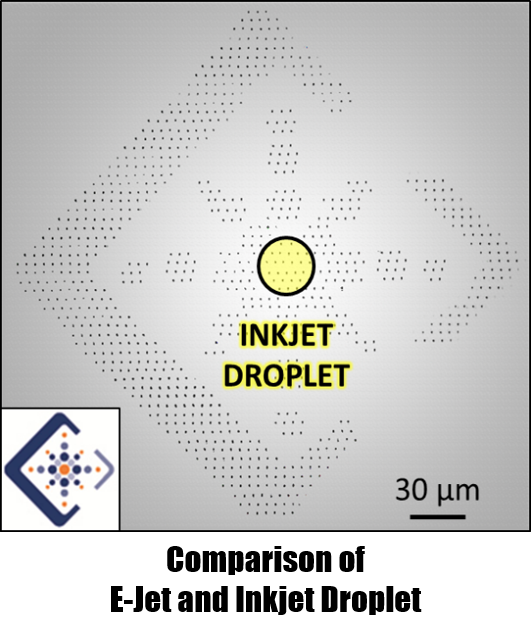

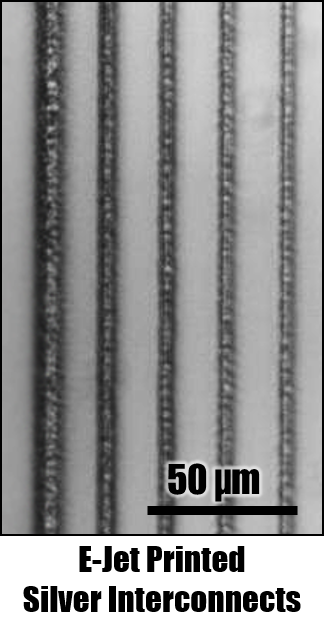

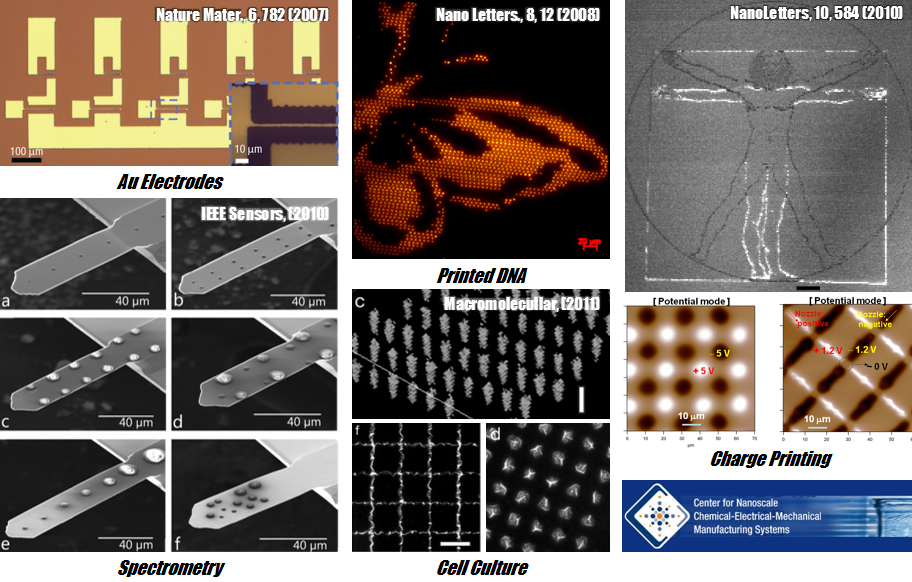

E-Jet printing has emerged as a high resolution alternative to other forms of direct solution-based fabrication approaches, such as ink-jet printing. The diameter of an E-Jet Printed droplet ranges from several hundreds of nanometer up to a few microns. Depending on the application, E-Jet printer can either produce discrete droplets or continuous lines. In the past decade, there has been various application for E-Jet printing, primarily for biosensing and printed electronics application.

|

|||||