Objective: A state-of-the-art Corrosion Research needs to connect three important areas: Predict-Protect-Prevent material degradation and failure. The AMR Corrosion Research Center pursues creation of corrosion-resistant structural materials and a de novo material manufacturing ecosystem to energize economic development through a strong emphasis on technology transfer to industry.

Motivation: Currently, the cost of corrosion related material degradation and failure is estimated to be $300B per year to the US economy. The DoD spends upwards of $23B in maintaining defense systems and infrastructure. In addition, the aging national infrastructure requires additional Trillions of dollars per decade for maintenance and replacement, a cost that continues to be a heavy burden on taxpayers. One of the grand challenges of this decade as identified by the National Academies is to predict and prevent environmental degradation of materials and their subsequent failure.

Smart Materials that Sense and Protect

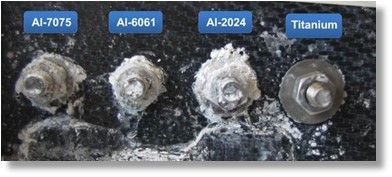

Surface protection currently involves the use of passive paints and coatings that require inspection at regular intervals and expensive maintenance. The vision is to develop structural materials that can sense and respond to corrosion. By designing a new class of uniquely superior and smart structures, UIUC is poised to lead as a hub to launch a new group of industries with unique material solutions to prevent corrosion.

Predict-and-Prevent Corrosion

Predictive corrosion modeling is the key to development of corrosion control strategies and prevent irreparable damage to key assets and infrastructure. ARIis distinctively recognized for its multiscale modeling capabilities in corrosion research. Our clients include Boeing Company, Honda R&D Americas, Triumph Composite Systems, Inc., U.S. Army Research Laboratory, GE Global Research and industries in the coatings development business.