Rashid Bashir

Rashid Bashir

Department of Bioengineering

Department of Electrical and Computer Engineering

University of Illinois at Urbana-Champaign

rbashir@illinois.edu

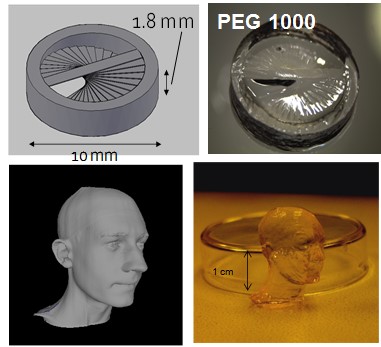

The integration of living cells with soft scaffolds can enable the fabrication of tissue constructs, biological machines, and soft robotics. These cell-based biological machines can be defined as a set of sub-components consisting of living cells and cell-instructive micro-environments that could eventually mimic organ functions and perform a range of prescribed tasks. The realization of biological machines and their sub-components will require a number of suitable cell sources, biomaterials, and enabling technologies. Here, we review our group’s recent efforts towards that goal of developing cell-based biological machines. Using a 3D printer, we have fabricated biological actuators made from hydrogels, cardiomyocytes, and skeletal muscles. The multi-material systems consisted of a “biological bimorph” cantilever structure as the actuator to power the device, and a base structure to define the asymmetric shape for locomotion. The cantilever structure was seeded with a sheet of contractile cardiomyocytes. We will also describe the development of 3D-printed, electrically paced skeletal muscle based “bio-bot” devices where skeletal myoblasts embedded in ECM proteins compacted around a hydrogel structure were used to create the power source of the biological walking machine. These technologies and devices could have potential applications in drug delivery, in power generation, and, especially, as organ mimics for surgical training and simulations of surgical procedures.

References:

- Cvetkovic, R. Raman, V. Chan, B. J. Williams, M. Tolish, P. Bajaj, M. L. Sakar, H. H. Asada, M. T. A. Saif, R. Bashir, “Three-Dimensionally Printed Biological Machines Powered by Skeletal Muscle,” PNAS, 2014. DOI: 10.1073/pnas.1401577111

- Chan, K. Park, M. B. Collens, H. Kong, T. A. Saif, and R. Bashir, “Walking Biological Machines with Hydrogels and Cardiomyocytes using a 3D Stereo-Lithographic Printer,” Sci. Rep. 2, 857; DOI:10.1038/srep00857, 2012.

- H. Jeong, V. Chan, C. Cha, P. Zorlutuna, C. Dyck, K. Jimmy Hsia, R. Bashir, and H. J. Kong, “‘Living’ Microvascular Stamp for Patterning of Functional Neovessels; Orchestrated Control of Matrix Property and Geometry,” Advanced Materials, Vol. 24, no. 1, Jan. 3, 2012.

Rashid Bashir is the Abel Bliss Professor and Department Head of Bioengineering at the University of Illinois at Urbana-Champaign. He was the Director of the Micro and Nanotechnology Laboratory (a campus-wide clean room facility) at Illinois, and is Co-Director of the campus-wide Center for Nanoscale Science and Technology, a collaboratory aimed at facilitating center grants and large initiatives around campus in the area of nanotechnology. He has authored or co-authored over 180 journal papers, over 200 conference papers and conference abstracts, and over 120 invited talks, and has been granted 34 patents. He is a Fellow of the IEEE, AIMBE, AAAS, and APS. His research interests include BioMEMS, lab on a chip, nano-biotechnology, interfacing biology and engineering from molecular to tissue scale, and applications of semiconductor fabrication to biomedical engineering, all applied to solve biomedical problems. He has been involved in 2 startups that have licensed his technologies.