Fiber Reinforced Concrete

Concrete is a brittle material and it can easily crack in the field. Fiber reinforcement is the most promising method of instilling greater ductility to the inherently brittle concrete matrix. Steel and polypropylene fibers, generally ranging in size from 1″-2″ long, have the largest share of the commercial market. Smaller fibers and even “microfibers” that are less than 1 mm in length have been studied.

![SEI image of steel fibers in cement paste. (Field width of 3.8 mm, x30) [SEI by Anne Abell and David A. Lange, UIUC]](http://publish.illinois.edu/concretemicroscopylibrary/files/2014/04/steelfibers.jpg)

SEI image of steel fibers in cement paste. (Field width of 3.8 mm, x30) [SEI by Anne Abell and David A. Lange, UIUC]

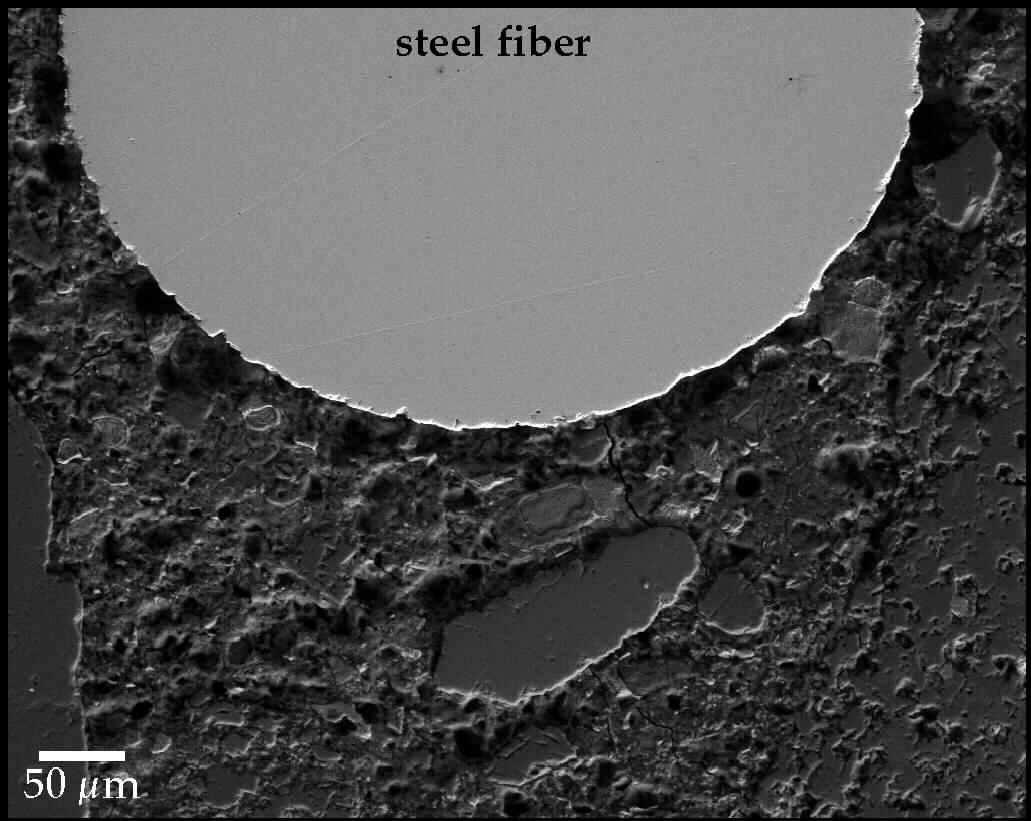

![This image and the image above it are BEI of a polished section showing a single steel fiber interface in a mortar having w/c=0.45. [Credit: Thomas Easley and Prof. Katherine T. Faber, Northwestern University]](http://publish.illinois.edu/concretemicroscopylibrary/files/2014/04/45m_crossSmallRight.jpg)

This image and the image above it are BEI of a polished section showing a single steel fiber interface in a mortar having w/c=0.45. [Credit: Thomas Easley and Prof. Katherine T. Faber, Northwestern University]

![This image and the image above it are BEI of a fracture surface showing a single steel fiber interface in a mortar having w/c=0.45. On the left is a mortar with no silica fume and on the right is a mortar with silica fume at 15% replacement of cement. This study illustrates how silica fume alters the fiber-matrix interface. [Credit: Thomas Easley and Prof. Katherine T. Faber, Northwestern University]](http://publish.illinois.edu/concretemicroscopylibrary/files/2014/04/45sf_surfSmallLeft.jpg)

This image and the image above it are BEI of a fracture surface showing a single steel fiber interface in a mortar having w/c=0.45. On the left is a mortar with no silica fume and on the right is a mortar with silica fume at 15% replacement of cement. This study illustrates how silica fume alters the fiber-matrix interface. [Credit: Thomas Easley and Prof. Katherine T. Faber, Northwestern University]